Prevent Irrigation System Damage This Winter

The irrigation system that provides your lawn, nursery, or crops with life-sustaining water throughout the growing season is susceptible to significant winter damage if all the water isn’t removed from the complex network of under- and above-ground pipes and hoses before temperatures fall below freezing. And, contrary to popular belief, simply “winterizing” the system by…

Read More >>

VisionLink Video Series

We’re rolling out a five-part series of videos to help you gain a better understanding of the new Cat® VisionLink® product and how its robust data will enable you to make better decisions and remove guesswork from fleet management.

Read More >>

CARTER TECHNICIAN EARNS COMPANY’SFIRST “MASTER TECHNICIAN” TITLE

WALDORF, MD – August 21, 2023. Chris Higgs, a Field Service Technician at Carter Machinery’s Waldorf, MD, location, recently earned the designation of becoming the company’s first Master Technician.

Read More >>

VisionLink® “Lunch & Learns” Help Customers See Technology’s Role in Fleet Management

Carter Machinery recently held a series of “Lunch & Learn” sessions throughout their Mid-Atlantic territory during which customers and Carter team members gained a better understanding of the new Cat® VisionLink product and how its robust data…

Read More >>

How to Maintain Cat® Steel Tracks

Your equipment’s steel track is essential to its productivity. That’s why in this two-minute video, we’re sharing best practices for taking care of the track and its components. You’ll see why a daily track check is important, how cleaning debris from the track can help you spot problems and prevent…

Read More >>

How to Test the Service Brake on Cat® Equipment

Follow the step-by-step instructions in this video to test your equipment’s service brake hold and learn how to gauge brake wear after removing the service brake indicator cap. The wear indicator pin provides an easy, visual check if whether there’s enough brake life remaining or of it’s time to call Carter Machinery for a brake…

Read More >>

How to Maintain Cat® Rubber Tracks

One of the easiest and most important maintenance activities that can protect and extend the life of Cat rubber tracks is a daily visual inspection that looks for signs of damage, including cuts or abrasions. Watch the video for more invaluable maintenance tips, including how to measure and adjust track tension to prevent wear and…

Read More >>

How to Service Ultra-High-Efficiency Cat® Filters

Ultra-High-Efficiency (UHE) Cat filters last longer than standard filters and excel at trapping contaminants – such as dirt and engine soot – that could harm the engine. This video explains how either a mechanical or electronic indicator will tell you it’s time to service the equipment’s UHE filter, and how to test to see if…

Read More >>

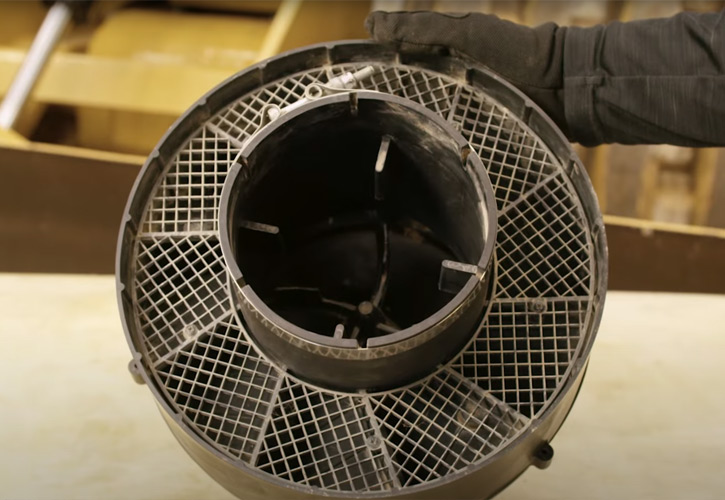

HOW TO SERVICE THE CAT® PRE-CLEANER ON AN ENGINE AIR FILTER

The pre-cleaner on your Cat machine helps extend engine air filter life as much as three times by trapping and ejecting debris before it ever reaches the air filter. Check out this video that shows you how to clear the pre-cleaner’s ports so debris can flow, and provides tips for removing stubborn debris without damaging…

Read More >>

How to Use Cat® Extreme Application Grease

Cat Extreme Application Grease is designed to stay where it’s placed, resisting water washout and protecting against rust as it lubricates joints. There are two types of grease, and this video will show you how to decide which one you should be using, even as you grease five times less frequently thanks to the grease’s…

Read More >>