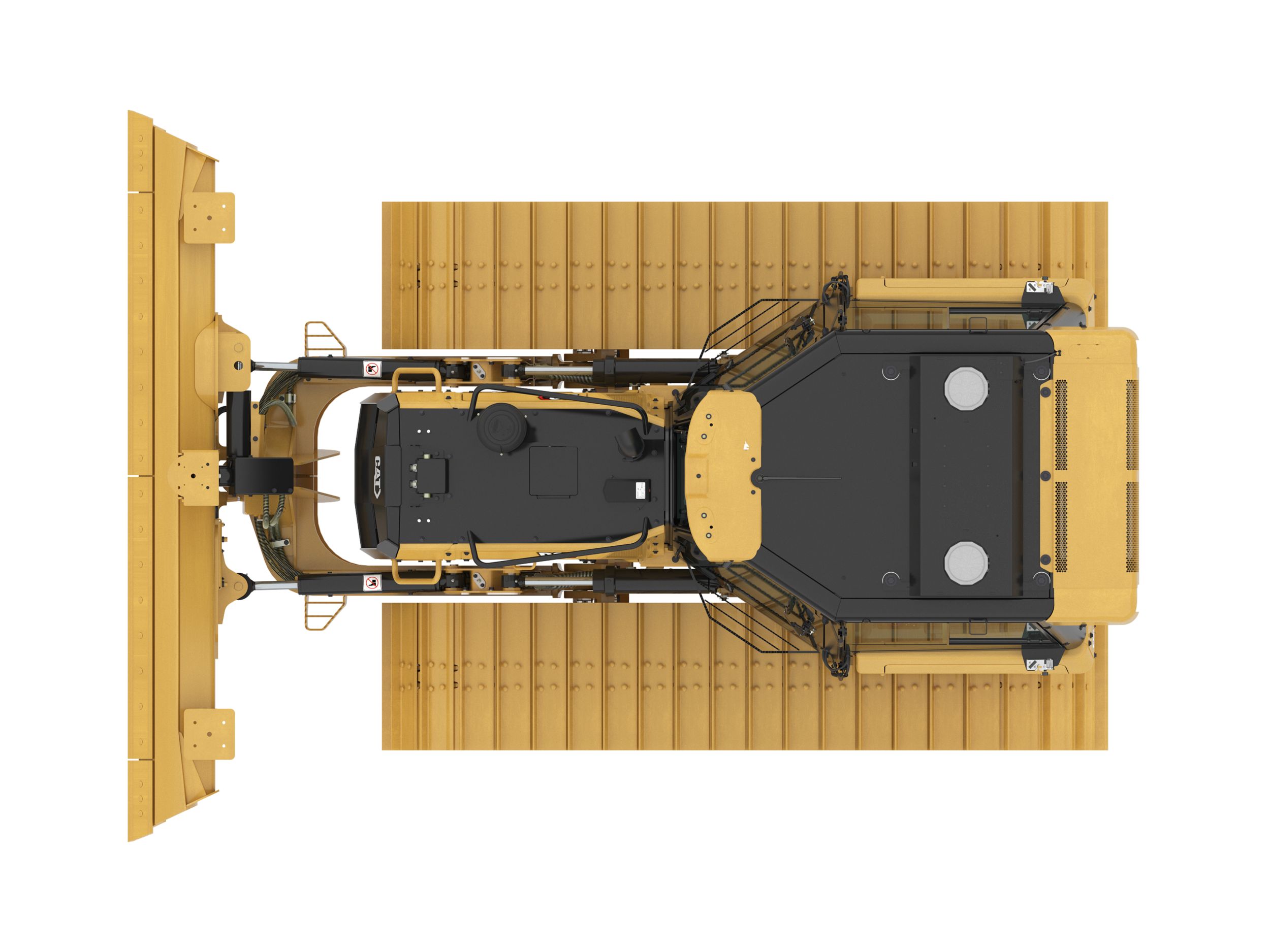

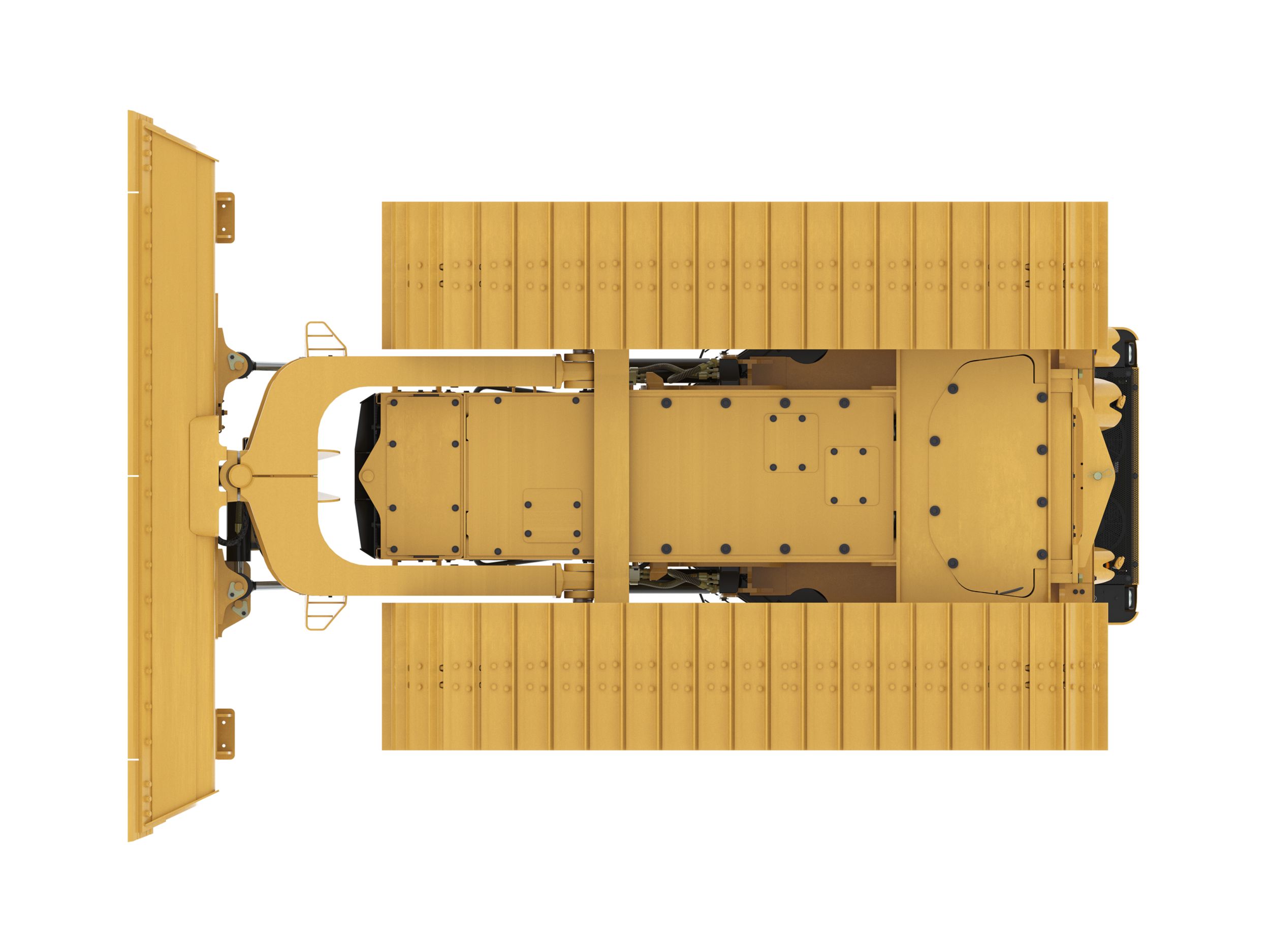

D2 Dozer

The Cat® D2 delivers superior performance and the broadest choice of technology features to help you get the most from your dozer. Nimble and responsive, it has power for dozing and finesse for grading. Fully hydrostatic transmission gives you seamless acceleration, so you can get the job done quickly. The load sensing system automatically optimizes ground speed based on load, for the greatest productivity and fuel efficiency.

Specifications

Equipment

Product Brochures

Attachments

Units:

Engine

Engine Model

Cat® C3.6

Power - Net

92 hp

68.8 kW

Displacement

220 in³

3.6 l

Net Power - 2,200 rpm - SAE J1349

92 hp

68.8 kW

Net Power - 2,200 rpm - ISO 9249/EEC 80/1269

92 hp

68.8 kW

Note (1)

Net power is tested per ISO 9249:2007 and SAE J1349:2011 and as advertised is the power available at the flywheel when the engine is equipped with fan, air intake system, exhaust system and alternator.

Engine

Power Train

Hydrostatic

Engine

Note (2)

All non-road U.S. EPA Tier 4 Final, EU Stage V, Japan 2014 (Tier 4 Final) and Korea Tier 4 Final diesel engines are required to use only Ultra Low Sulfur Diesel (ULSD) fuels containing 15 ppm EPA/10 ppm EU (mg/kg) sulfur or less.

Weights

Operating Weight

18382 lb

8338 kg

Operating Weight

18382 lb

8338 kg

Operating Weight - LGP

19066 lb

8648 kg

Note (2)

For machine with ripper, add 554 kg (1,222 lb).

Note (1)

Specifications shown are for machine equipped with dozer blade, EROPS cab, back-up alarm, operator, coolant, lubricants and full fuel tank.

Cab

FOPS

ISO 3449:2005 Level II

ROPS

ISO 3471:2008

Transmission

Drive Pumps

1

Maximum Travel Speed - Forward

5.6 mile/h

9 km/h

Relief Valve Settings

7033 psi

48500 kPa

Maximum Travel Speed - Reverse

6.2 mile/h

10 km/h

Track Motors

2

Undercarriage

Length - Track on Ground - LGP

89 in

2248 mm

Track Gauge

61 in

1550 mm

Number of Rollers - Each Side

7

Track Gauge - LGP

68 in

1725 mm

Ground Pressure - LGP

4.3 psi

29.7 kPa

Shoe Width - Standard

18 in

460 mm

Shoe Width - LGP

25 in

635 mm

Number of Shoes - Each Side - Sealed and Lubricated Track (SALT) Undercarriage

43

Undercarriage

Number of Shoes - Each Side - Abrasion Undercarriage

38

Ground Pressure

5.7 psi

39.5 kPa

Length of Track on Ground

89 in

2248 mm

Service Refill Capacities

Fuel Tank

51.5 gal (US)

195 l

Crankcase - With Filter

2.8 gal (US)

10.5 l

Final Drive - Each - LGP

2.6 gal (US)

10 l

Cooling System

5 gal (US)

19 l

Transmission - Hydraulic Tank

23.8 gal (US)

90 l

Diesel Exhaust Fluid (DEF) Tank

4.9 gal (US)

19 l

Service Refill Capacities

Final Drives - Each Side

2.6 gal (US)

10 l

Hydraulic Controls

Pump Output

17.2 gal/min

65 l/min

Relief Valve Settings

2988 psi

20600 kPa

Ripper

Type

Parallelogram

Number of Shanks

3

Height

6.5 in

165 mm

Weight

1222 lb

554 kg

Maximum Digging Depth

13.3 in

337.5 mm

Maximum Ground Clearance Under Tip

17.6 in

448 mm

Overall Width

67.3 in

1710 mm

Maximum Reach - Ground Line

30.2 in

766 mm

Air Conditioning System

Air Conditioning

The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.8 kg of refrigerant which has a CO2 equivalent of 2.574 metric tonnes.

Dimensions

BLADE: Digging Depth - LGP

23.2 in

589 mm

BLADE: Blade Cutting Edge Angle, Adjustable - LGP

52° to 58°

BLADE: Blade Lift Height - LGP

27.9 in

708 mm

BLADE: Blade Width - LGP

124 in

3149 mm

BLADE: Blade Width at Maximum Angle - LGP

113.1 in

2874 mm

Track Gauge - LGP

67.9 in

1725 mm

Ground Clearance - LGP

13 in

332 mm

BLADE: Blade Height - LGP

35.8 in

910 mm

Overall Length - With Blade - LGP

168.2 in

4272 mm

BLADE: Blade Capacity (SAE) - LGP

2.42 yd³

1.85 m³

BLADE: Maximum Tilt - LGP

17.2 in

438 mm

BLADE: Maximum Angle (either side) - LGP

25°

Dimensions

BLADE: Maximum Angle (either side) - Standard

25°

Ground Clearance - Standard

13 in

332 mm

Overall Length - With Blade - Standard

168.5 in

4281 mm

Dimensions

Note

Abrasion Undercarriage

Dimensions

BLADE: Blade Cutting Edge Angle, Adjustable - Standard

52° to 58°

BLADE: Maximum Tilt - Standard

15.2 in

387 mm

Track Gauge - Standard

61 in

1550 mm

BLADE: Digging Depth - Standard

23.3 in

593 mm

BLADE: Blade Width - Standard

109.5 in

2782 mm

BLADE: Blade Lift Height - Standard

29.3 in

743 mm

BLADE: Blade Capacity (SAE) - Standard

2.59 yd³

1.98 m³

BLADE: Blade Width at Maximum Angle - Standard

100.1 in

2542 mm

Note

With Ripper Attachment (add to Length of Basic Dozer) - 1177 mm (46.3 in)

BLADE: Blade Height - Standard

39.8 in

1010 mm

Dimensions

Length of Basic Dozer (without blade) - LGP

129.5 in

3290 mm

Width of Dozer (standard shoes, no blade) - Standard

79.1 in

2010 mm

Dozer Height - LGP

108.9 in

2765 mm

Dozer Height - Standard

108.9 in

2765 mm

Width of Dozer (standard shoes, no blade) - LGP

92.9 in

2360 mm

Length of Basic Dozer (without blade) - Standard

129.5 in

3290 mm

Retrieval Winch

Maximum Line Speed - Full Drum

79 ft/min

24 m/min

Maximum Line Speed - Bare Drum

50 ft/min

15 m/min

Weight

1747 lb

794 kg

Drum Capacity - Optional Cable

195 ft

59 m

Rope Diameter - Recommended

0.63 in

16 mm

Winch Drive

Hydraulic

Rope Diameter - Optional

0.75 in

19 mm

Drum Capacity - Recommended Cable

277 ft

84 m

Maximum Line Pull - Full Drum

20350 lb

9231 kg

Speed

Variable

Maximum Line Pull - Bare Drum

32150 lb

14583 kg

Control

Hydraulic

Overall width

27.91 in

709 mm

Drum Width

9.65 in

245 mm

Drum Diameter

8 in

203.2 mm

Winch Length

35.63 in

905 mm

Throat Clearance

5.6 in

141.4 mm

High Performance Winch

Maximum line pull – bare drum

40000 lb

18144 kg

Drum capacity – recommended cable

371 ft

113 m

Winch length

27.76 in

705 mm

Overall width

29.2 in

741 mm

Control

Hydraulic

Maximum line speed – bare drum

131 ft/min

40 m/min

Maximum line speed – full drum

207 ft/min

63 m/min

Drum width

10.8 in

274 mm

Drum capacity – optional

256 ft

78 m

Throat clearance

6.75 in

171.5 mm

Weight

1345 lb

610 kg

Rope diameter – recommended

0.63 in

16 mm

Speed

Variable

Maximum line pull – full drum

25000 lb

11340 kg

Drum diameter

10 in

254 mm

Rope diameter – optional

0.75 in

19 mm

Winch drive

Hydrostatic

Standard Equipment

POWER TRAIN

ELECTRICAL

UNDERCARRIAGE

HYDRAULIC

CAT TECHNOLOGY

ATTACHMENTS

OPERATOR ENVIRONMENT