6030 Hydraulic Shovel

The Cat® 6030 Hydraulic Mining Shovel is owned by more customers than any other product in the Cat portfolio — and for good reason. It provides the most powerful engine output in its class, along with the mobility and flexibility you need from a 300-tonne machine, to deliver the productivity you expect, with the reliability you demand.

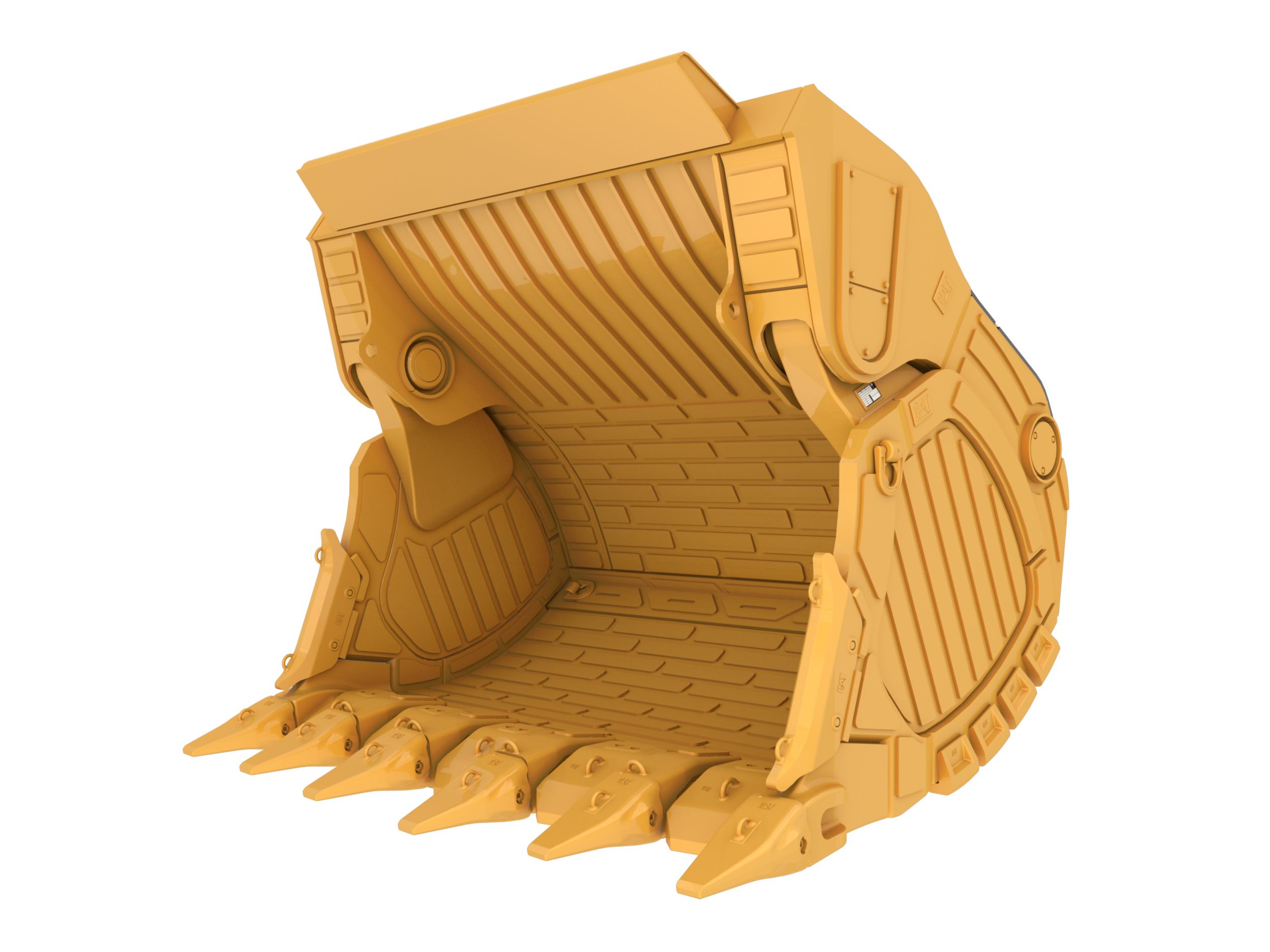

The 6030 offers a standard bucket capacity of 17 m3 (22.2 yd3) in backhoe configuration, and 16.5 m3 (21.5 yd3) in face shovel (FS) configuration with the unique Cat TriPower™ system. The 6030 is ideal to load Cat 777 to 793 mining trucks.

But we’re always looking for ways to make the 6030 better. The only shovel in its size class offered with dual engines, it’s available with a Tier 4 Final engine solution that eliminates the need for Diesel Exhaust Fluid (DEF), saving time and cost during maintenance.