226D3 Skid Steer Loader

The Cat® 226D3 Skid Steer Loader, with its radial lift design, delivers impressive mid-lift reach and excellent digging performance with outstanding drawbar power.

Specifications

Equipment

Product Brochures

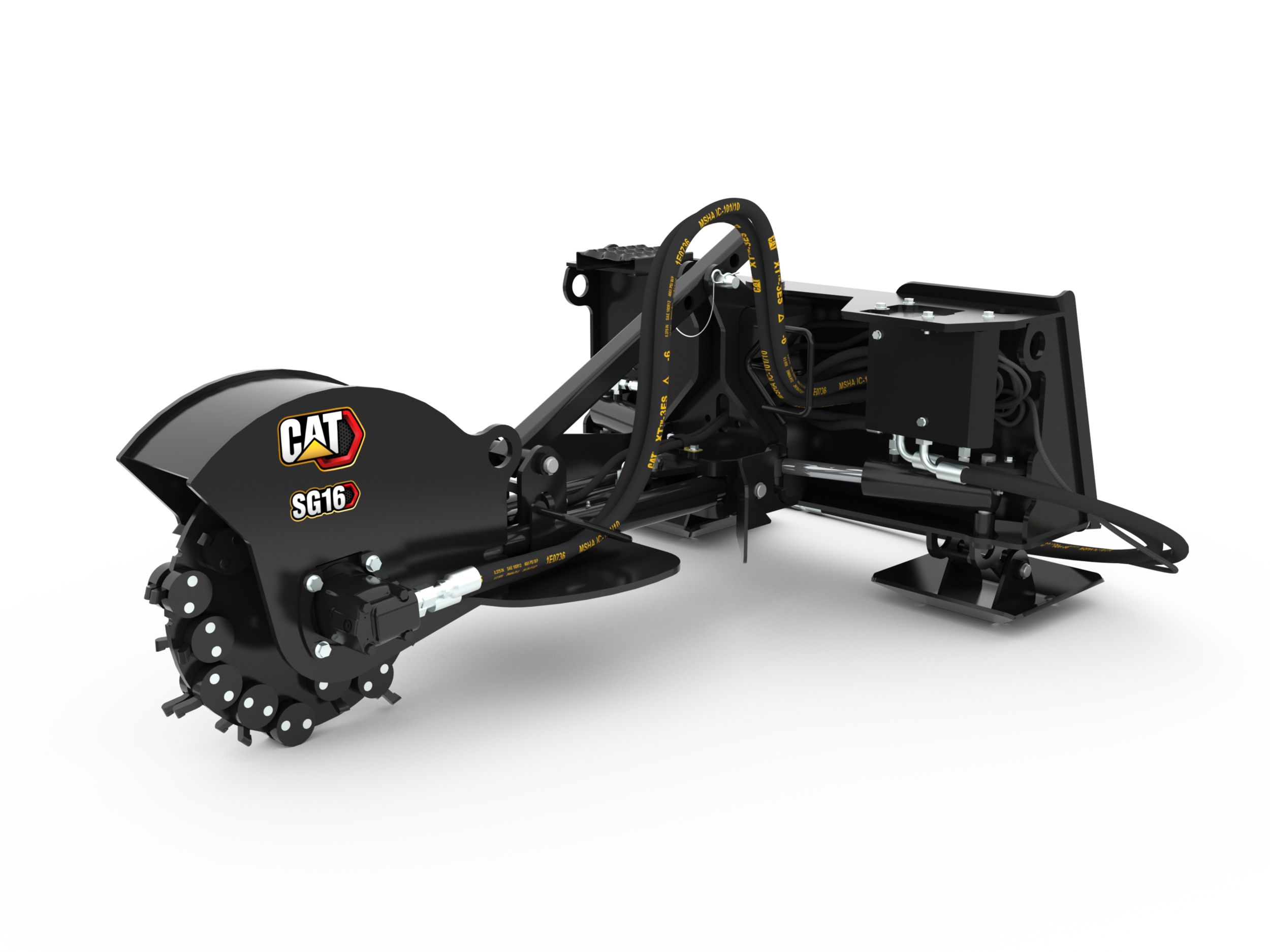

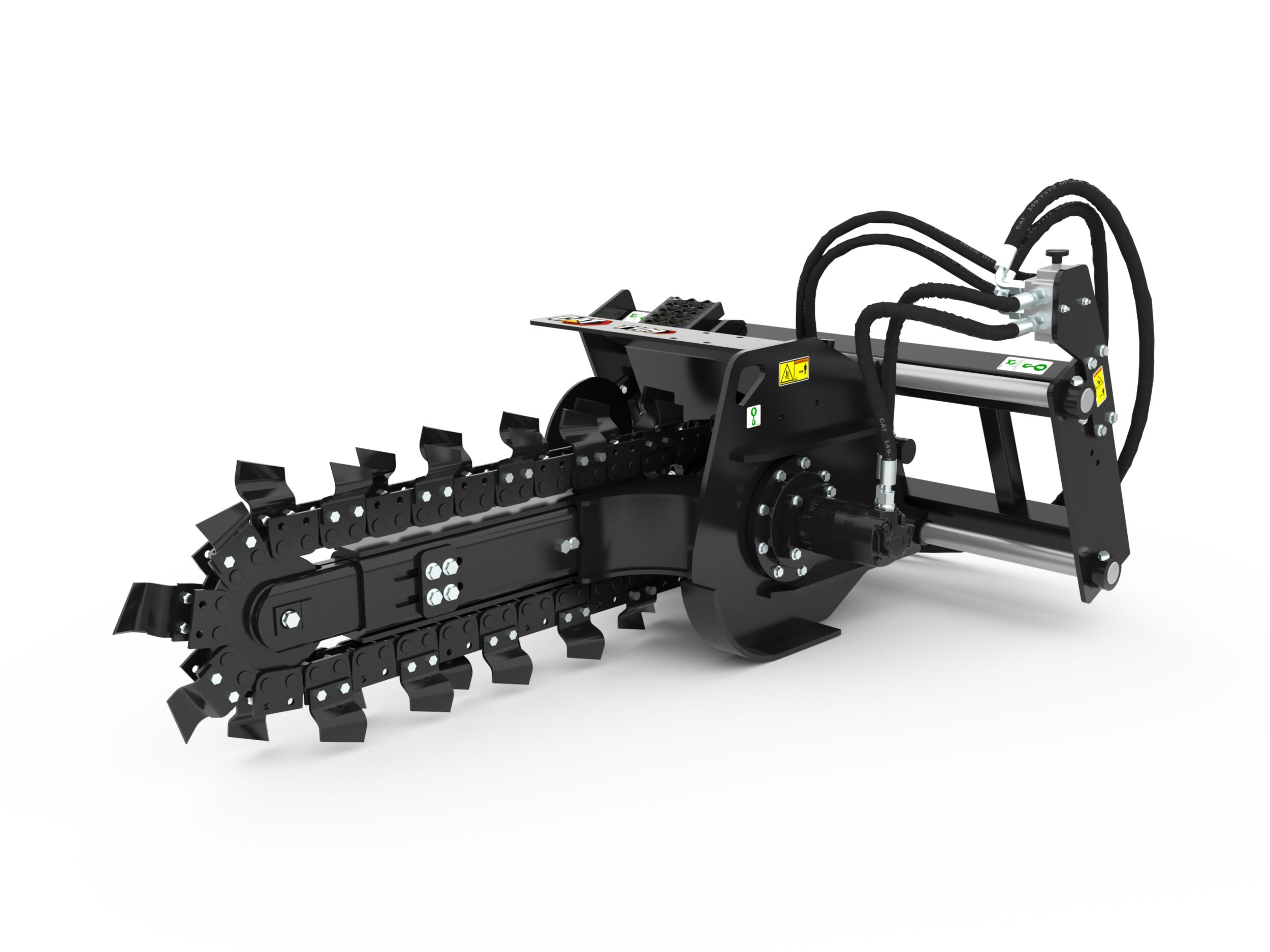

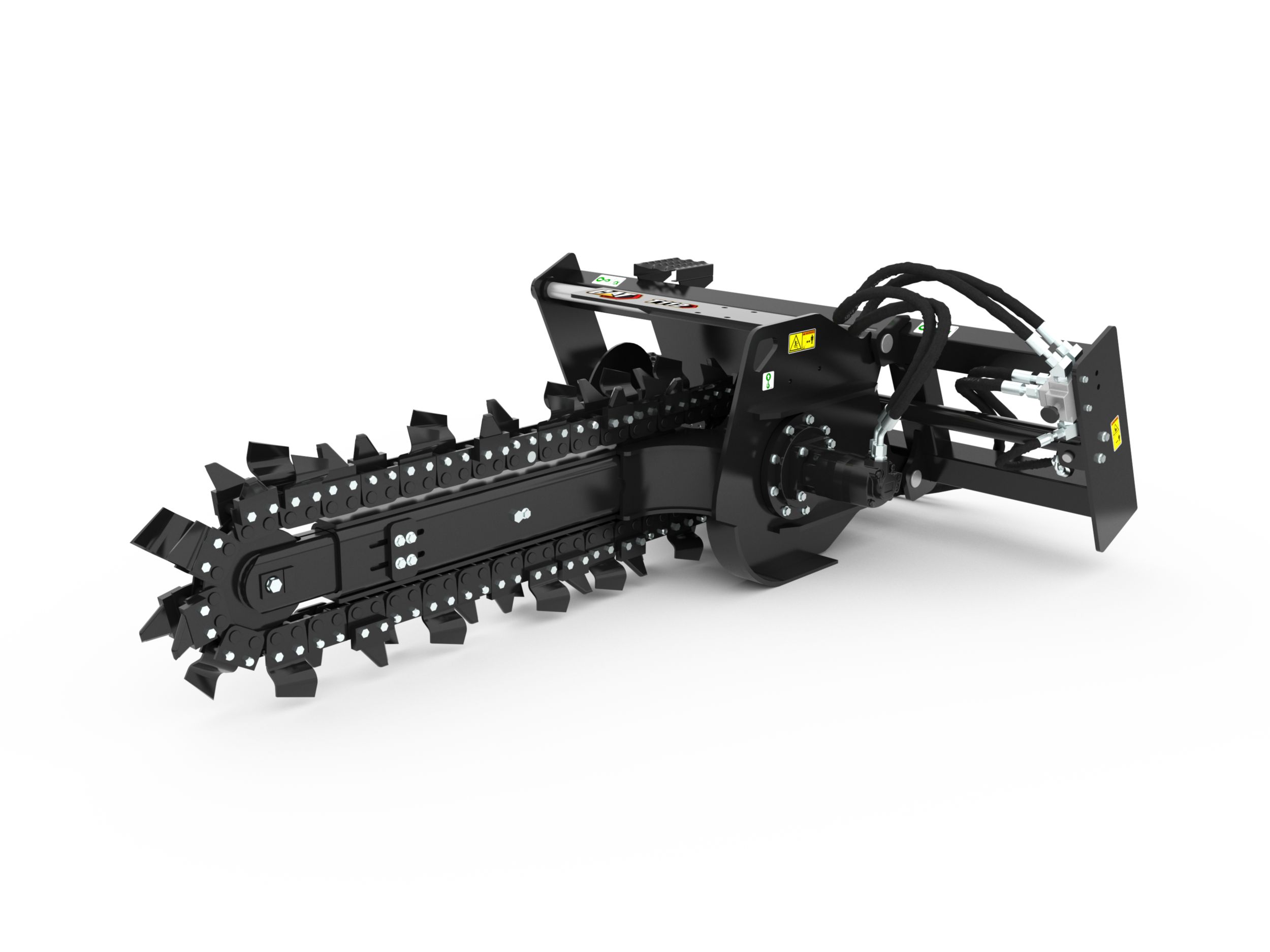

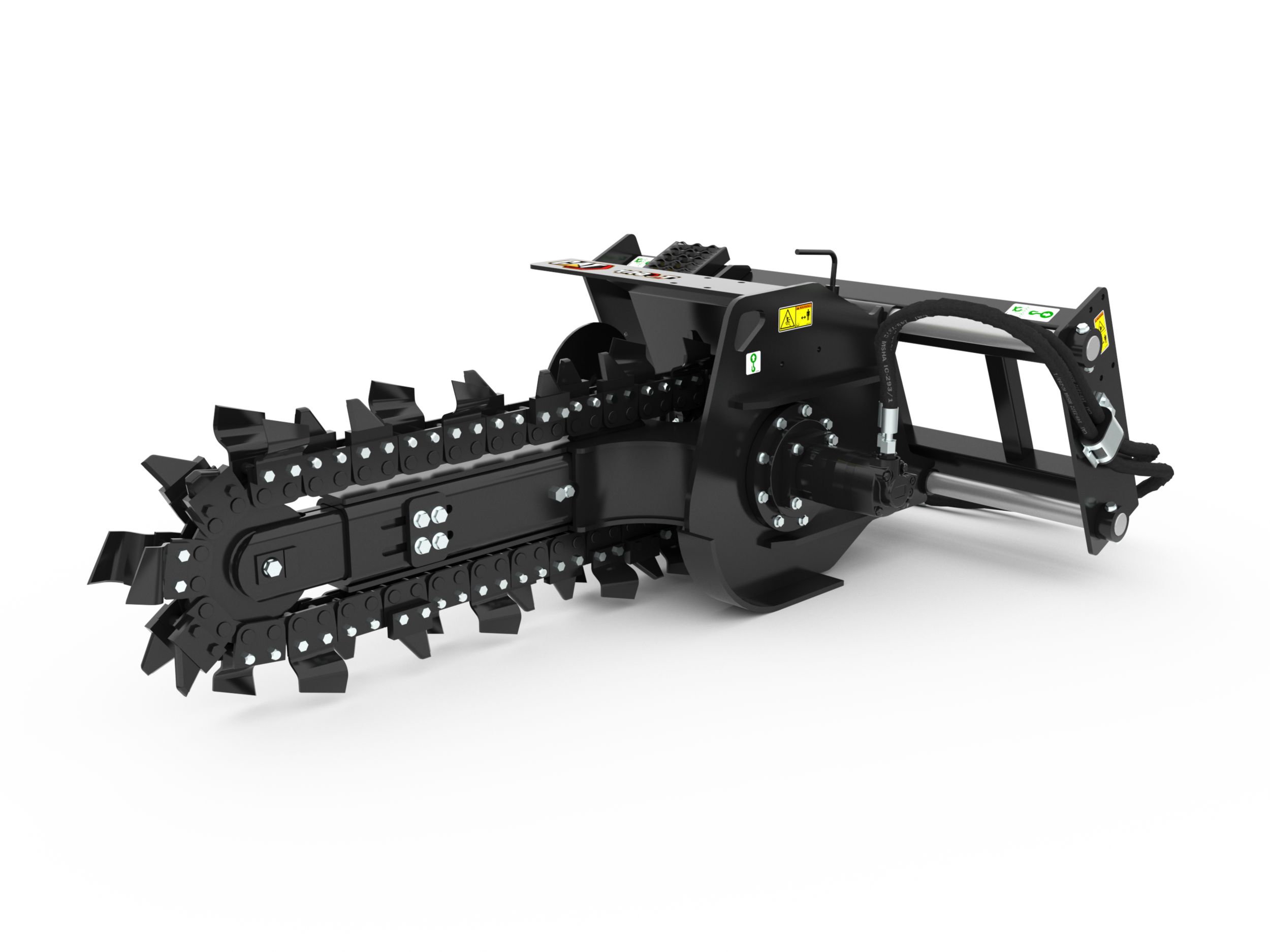

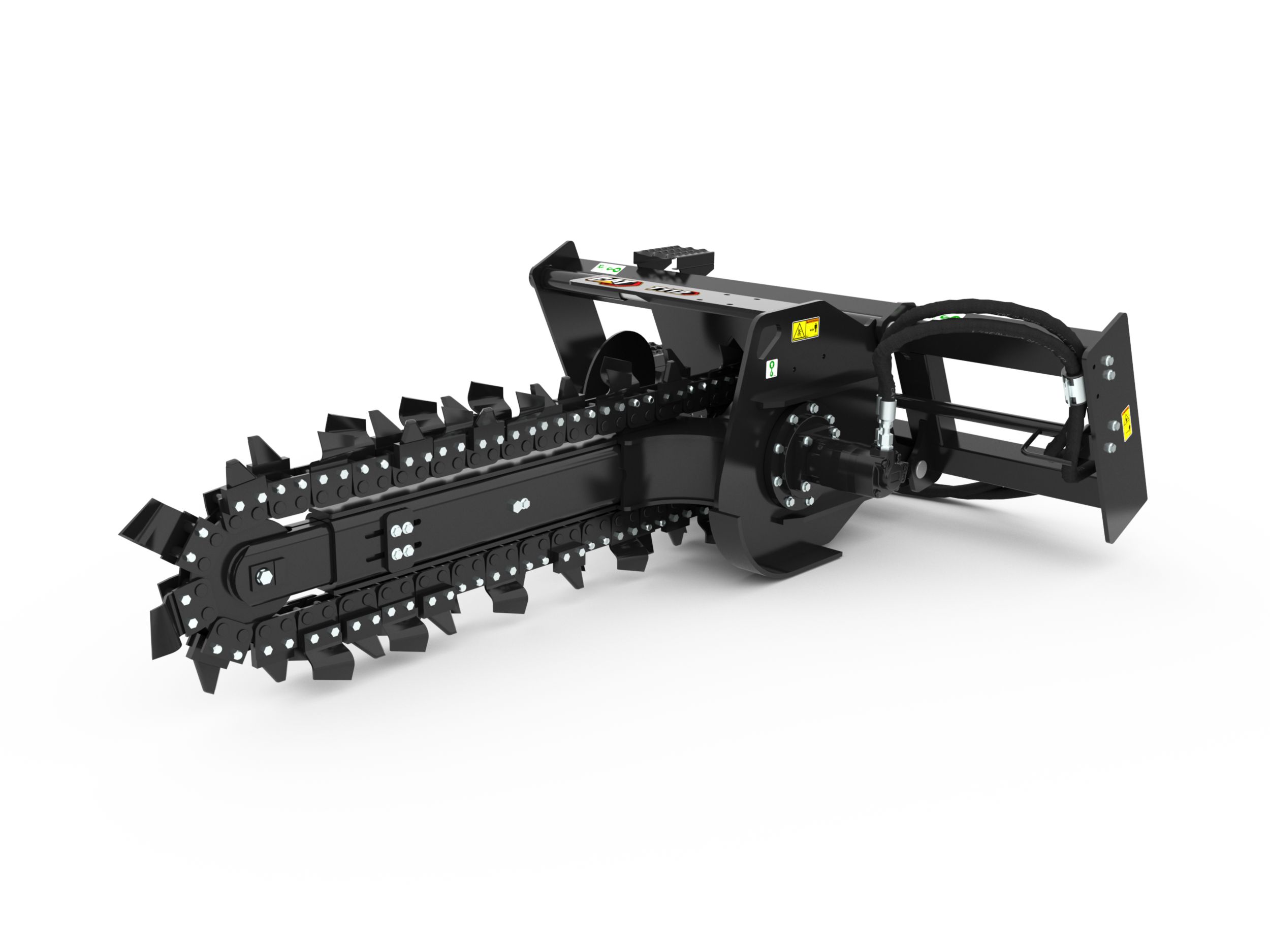

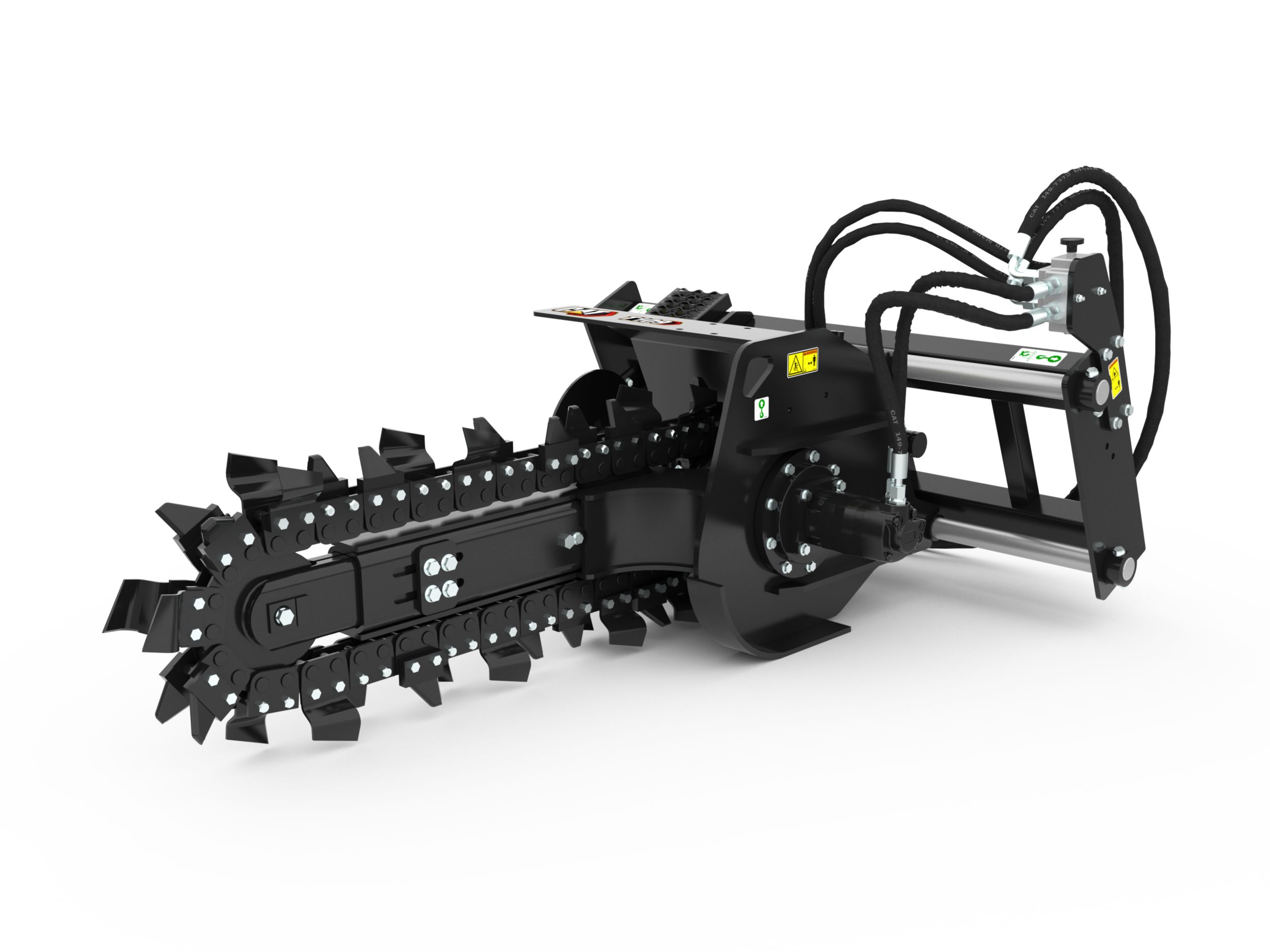

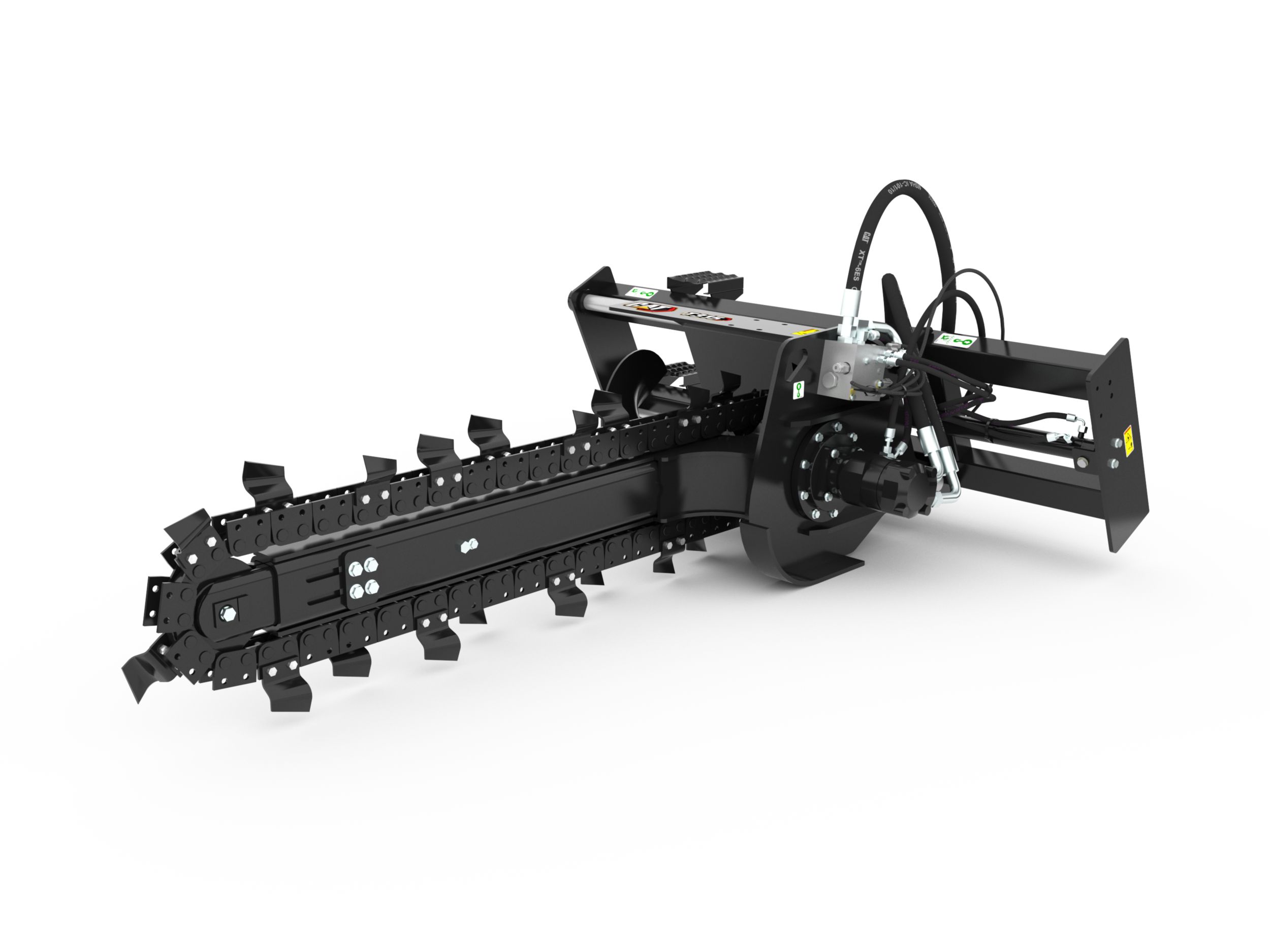

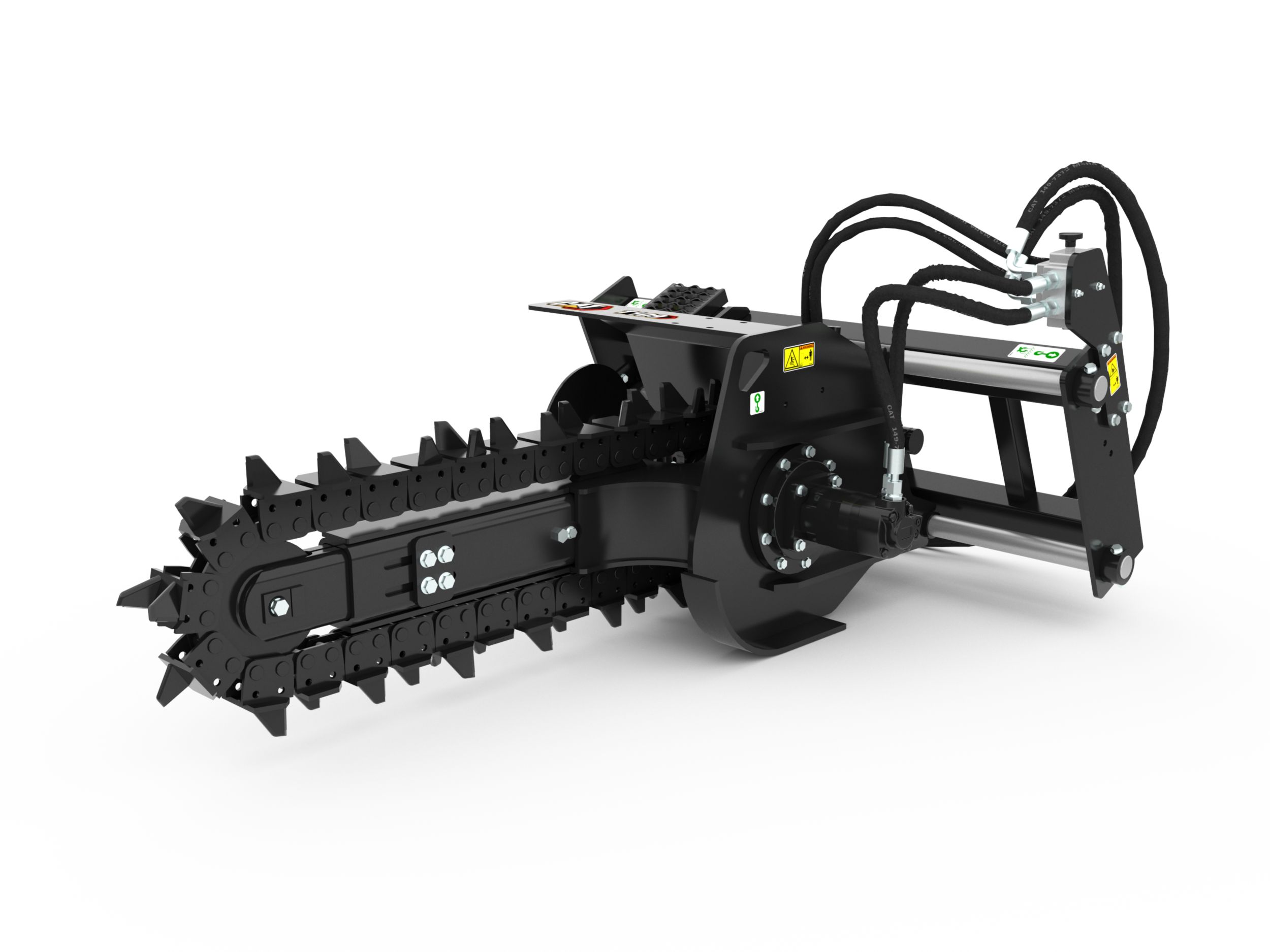

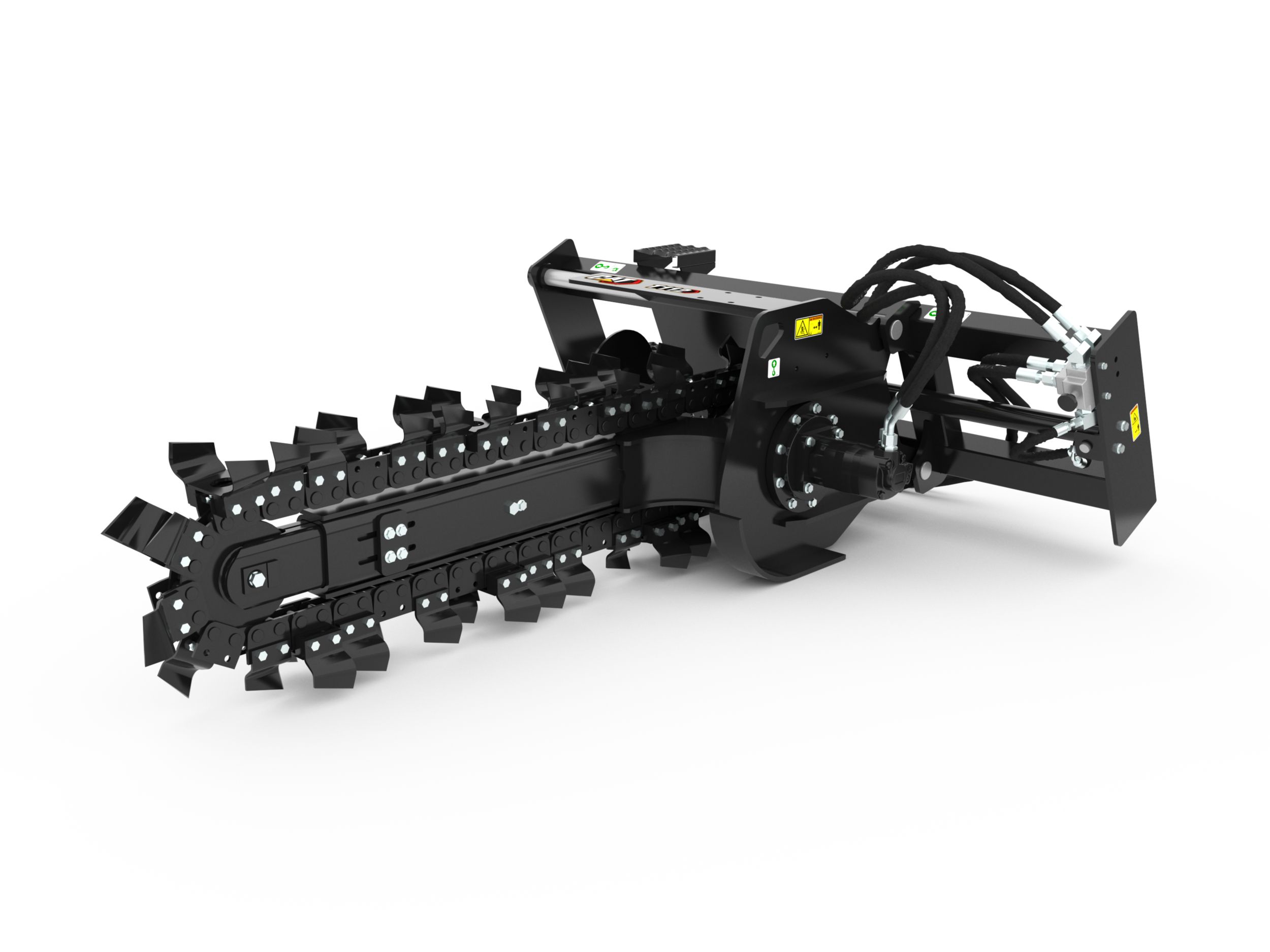

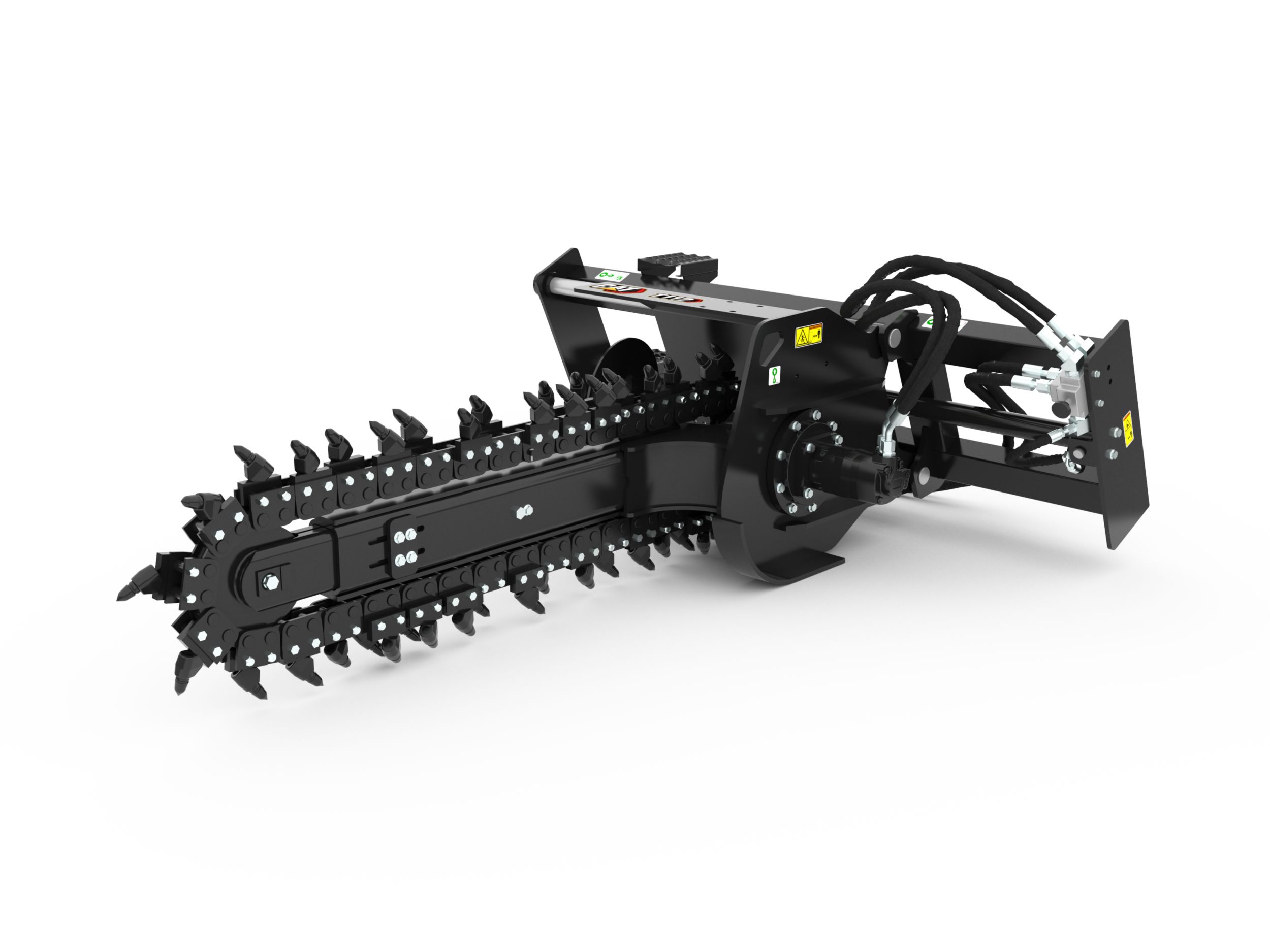

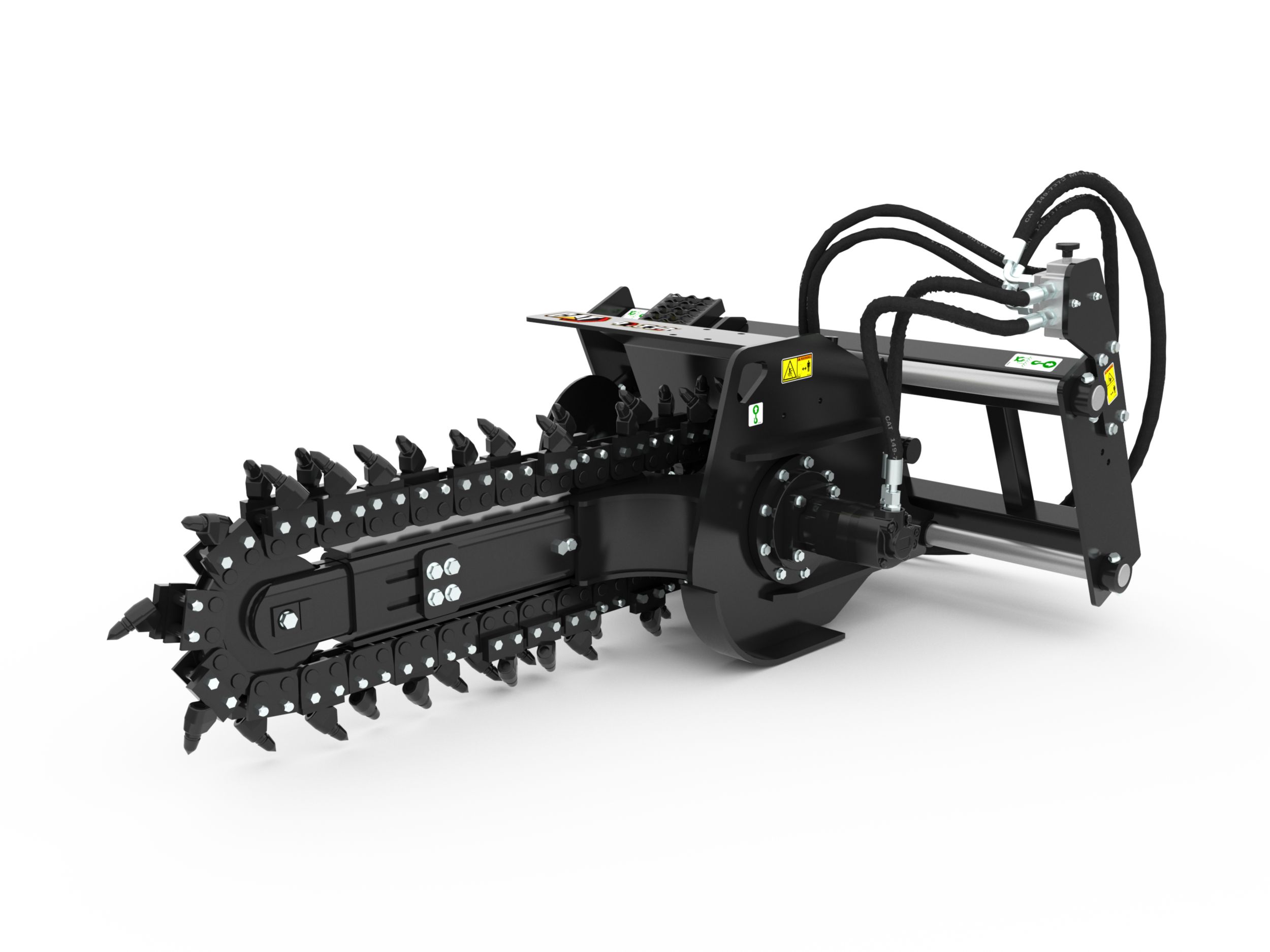

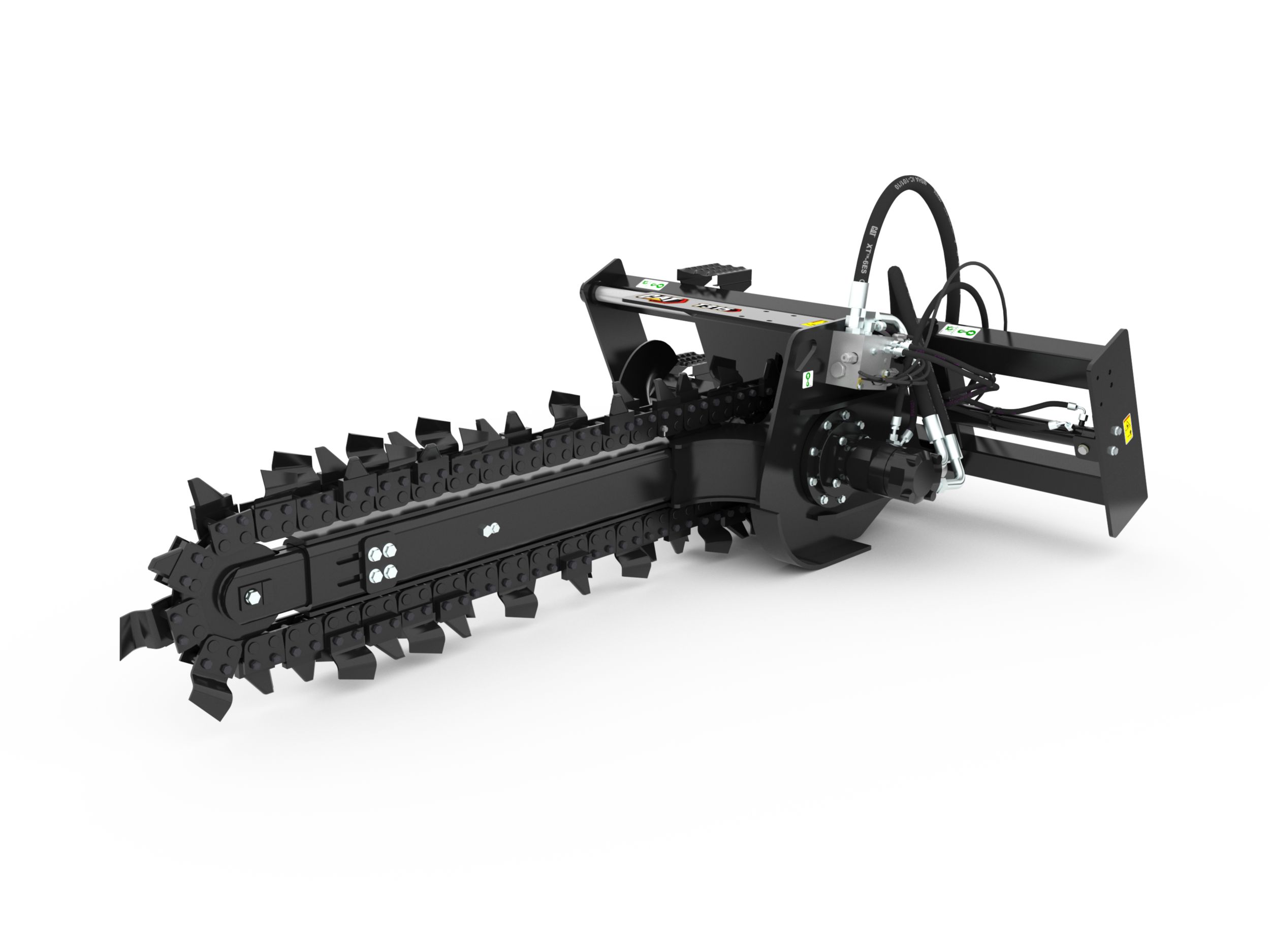

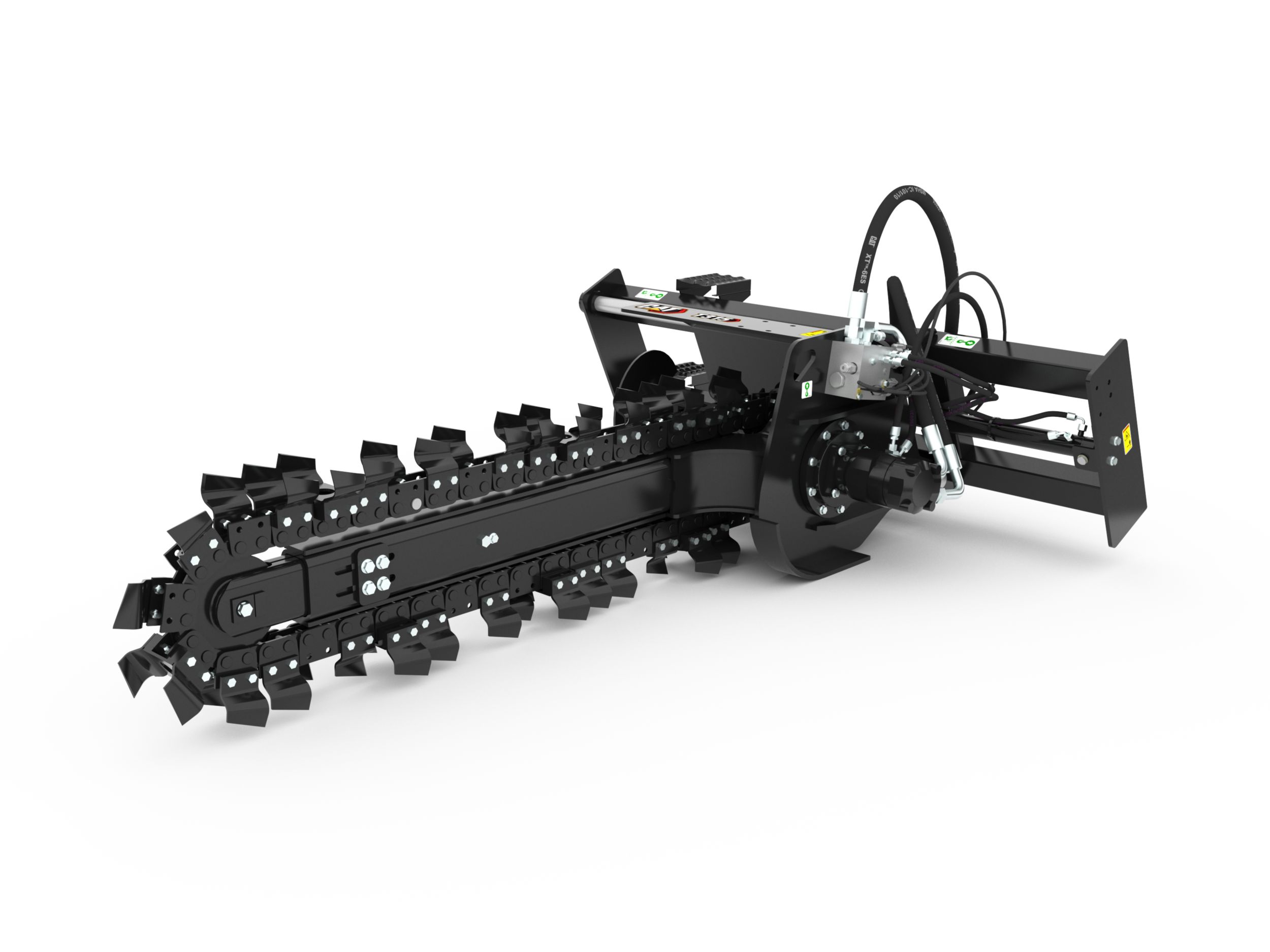

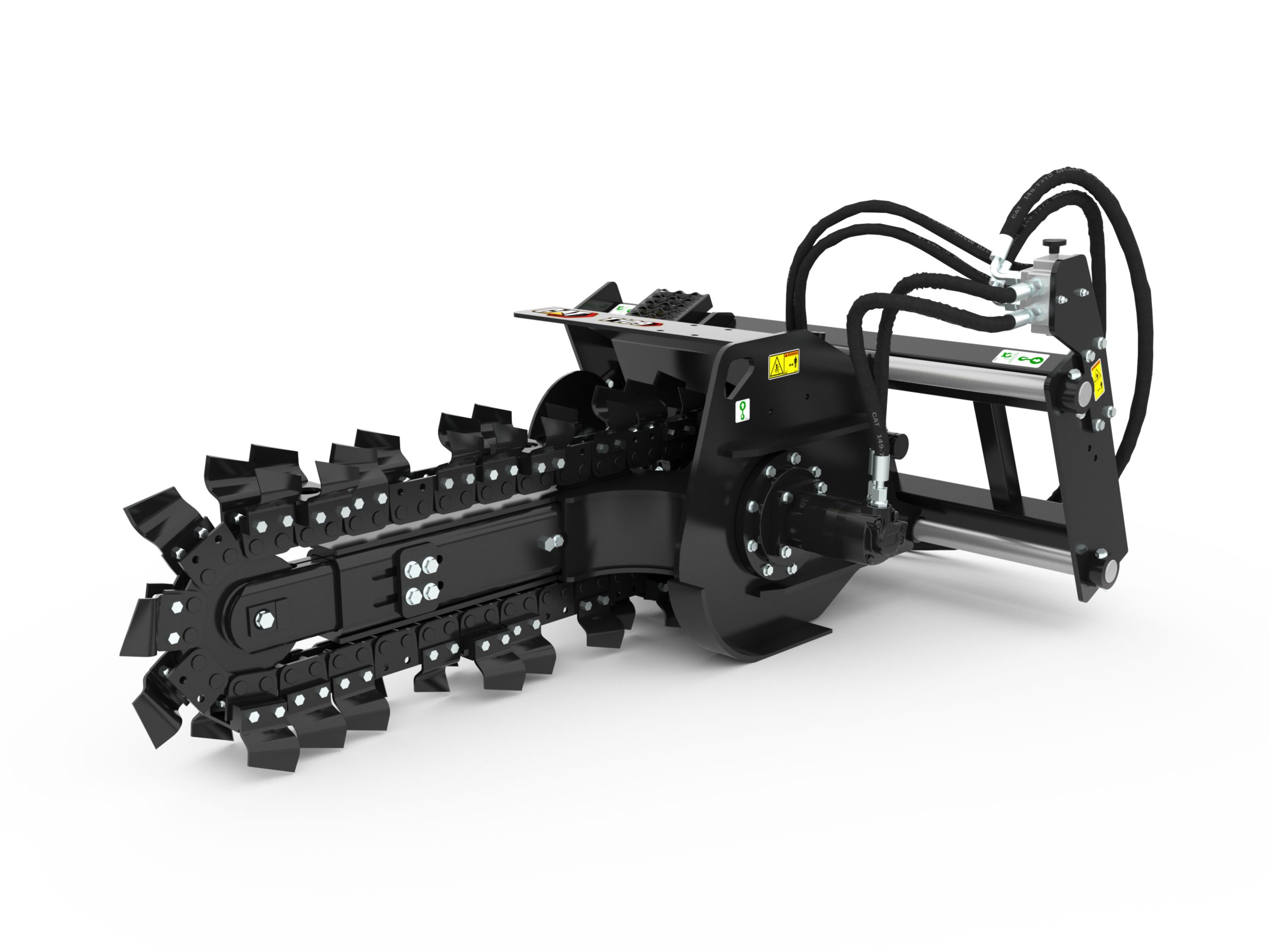

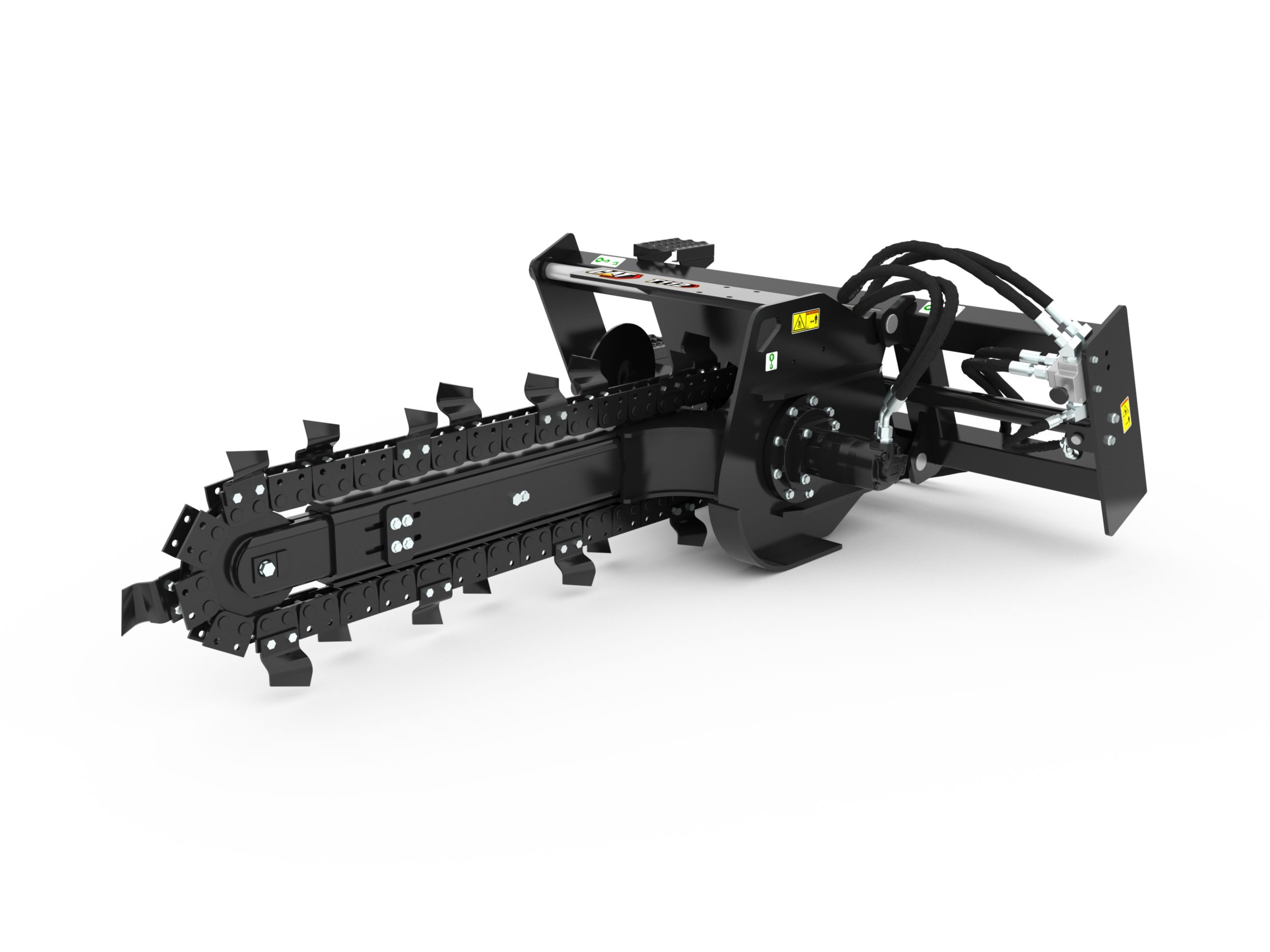

Attachments

Units:

Engine

Gross Power - SAE J1995

67.1 hp

50.1 kW

Operating Specifications

Rated Operating Capacity

1550 lb

705 kg

Weights

Operating Weight

5849 lb

2653 kg

Dimensions

Wheel Base

41.5 in

1054 mm

Length - With Bucket on Ground

127.3 in

3234 mm

Length - Without Bucket

99.4 in

2524 mm

Height - Top of Cab

79.8 in

2028 mm

Vehicle Width over Tires

58.9 in

1497 mm

Maximum Overall Height

143.8 in

3652 mm

Bucket Pin Height - Maximum Lift

110.9 in

2818 mm

Bucket Pin Height - Carry Position

8.5 in

215 mm

Reach - Maximum Lift/Dump

21 in

533 mm

Clearance at Maximum Lift and Dump

81.8 in

2077 mm

Ground Clearance

6.9 in

175 mm

Departure Angle

27.9°

Maximum Dump Angle

46.7°

Rack Back Angle - Maximum Height

88.9°

Bumper Overhang - Behind Rear Axle

35.2 in

8944 mm

Turning Radius from Center - Bucket

77.8 in

1977 mm

Maximum Reach - With Arms Parallel to Ground

50.7 in

1288 mm

Turning Radius from Center - Machine Rear

59.6 in

1513 mm

Turning Radius from Center - Coupler

43.5 in

1104 mm

Note

* Operating Weight, Operating Specifications and Dimensions all based on 75 kg (165 lb) operator, all fluids, single speed, 1576 mm (62 in) low profile bucket, Cat 10 × 16.5 tires, standard flow hydraulics, C1 cab (OROPS, mechanical seat), 850 CCA battery, manual quick coupler, no self level and no optional counterweights (unless otherwise noted).

Hydraulic System

Hydraulic Flow - Standard - Loader Hydraulic Pressure

3336 psi

23000 kPa

Hydraulic Flow - High Flow - Maximum Loader Hydraulic Pressure

3336 psi

23000 kPa

Hydraulic Flow - Standard - Hydraulic Power (Calculated)

33.5 hp

26.5 kW

Hydraulic Flow - High Flow - Hydraulic Power (Calculated)

50.9 hp

38 kW

Hydraulic Flow - Standard - Loader Hydraulic Flow

18 gal/min

69 l/min

Hydraulic Flow - High Flow - Maximum Loader Hydraulic Flow

26 gal/min

99 l/min

Cab

ROPS

ISO 3471:2008

FOPS

ISO 3449:2005 Level I

Power Train

Travel Speed - Forward or Reverse - One Speed

7.6 mile/h

12.3 km/h

Travel Speed - Forward or Reverse - Two Speed Option

11.1 mile/h

17.8 km/h

Service Refill Capacities

Chain Box - Each Side

1.8 gal (US)

7 l

Cooling System

3.2 gal (US)

12 l

Engine Crankcase

2.6 gal (US)

10 l

Fuel Tank

15.1 gal (US)

57 l

Hydraulic System

11.9 gal (US)

45 l

Hydraulic Tank

9 gal (US)

34 l

Air Conditioning System (if equipped)

Air Conditioning

The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 0.81 kg of refrigerant which has a CO2 equivalent of 1.158 metric tonnes.

Engine

Net Power - SAE 1349

65.8 hp

49.1 kW

Displacement

134.3 in³

2.2 l

Stroke

3.9 in

100 mm

Bore

3.3 in

84 mm

Engine Model

Cat C2.2 CRDI

Weights

Note

* Operating Weight, Operating Specifications and Dimensions all based on 75 kg (165 lb) operator, all fluids, single speed, 1576 mm (62 in) low profile bucket, Cat 10 × 16.5 tires, standard flow hydraulics, C1 cab (OROPS, mechanical seat), 850 CCA battery, manual quick coupler, no self level and no optional counterweights (unless otherwise noted).

Engine

Peak Torque - 1,500 rpm - SAE J1995

153 ft·lbf

208 N·m

Net Power - ISO 9249

66.5 hp

49.6 kW

Operating Specifications

Rated Operating Capacity with Optional Counterweight

1650 lb

750 kg

Tipping Load

3100 lb

1410 kg

Breakout Force - Tilt Cylinder

3927 lb

1781 kg

Note

* Operating Weight, Operating Specifications and Dimensions all based on 75 kg (165 lb) operator, all fluids, single speed, 1576 mm (62 in) low profile bucket, Cat 10 × 16.5 tires, standard flow hydraulics, C1 cab (OROPS, mechanical seat), 850 CCA battery, manual quick coupler, no self level and no optional counterweights (unless otherwise noted).

Noise Level

Outside Cab***

102 dB(A)

102 dB(A)

Inside Cab**

83 dB(A)

83 dB(A)

Note (3)

***The labeled sound power level for the CE marked configurations when measured according to the test procedure and conditions specified in 2000/14/EC.

Note (1)

Cab and Rollover Protective Structures (ROPS) are standard in North America and Europe.

Note (2)

**The declared dynamic operator sound pressure levels per ISO 6396:2008. The measurements were conducted with the cab doors and windows closed and at 70% of the maximum engine cooling fan speed. The sound level may vary at different engine cooling fan speeds.

Standard Equipment

ELECTRICAL

OPERATOR ENVIRONMENT

POWER TRAIN

OTHER

MANDATORY EQUIPMENT