963 Track Loader

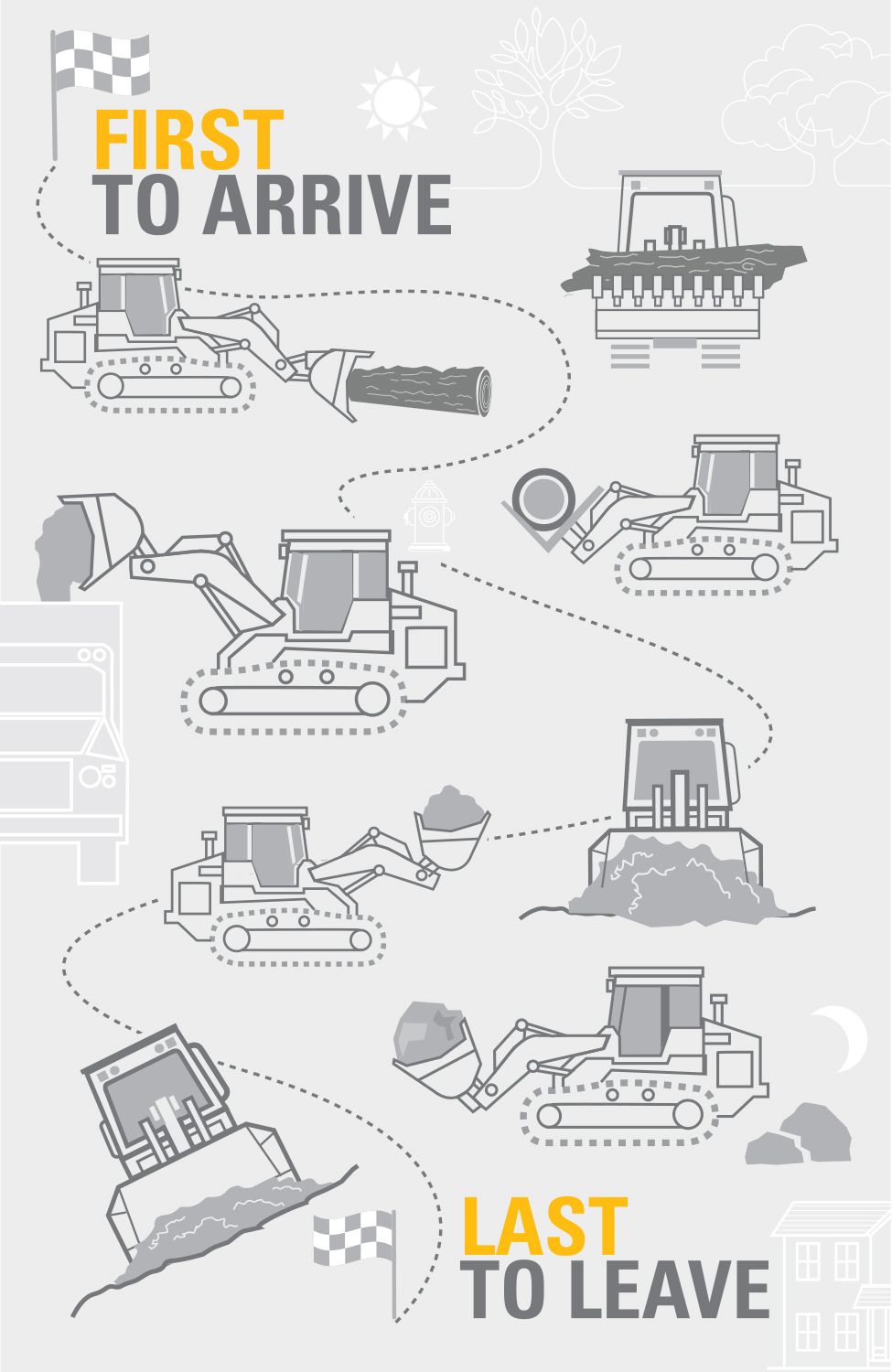

Save money and transport time with one rugged machine that does it all – land clearing, digging, grading, truck loading, slope work and more. Crawler loaders give you lower ground pressure and better traction so you can start the job sooner, and work longer, in all kinds of underfoot conditions. Cat® Track Loaders give you all this, plus outstanding performance and fuel efficiency.

Specifications

Equipment

Product Brochures

Attachments

Units:

Engine

Flywheel Power

202 hp

151 kW

Engine Model

Cat C7.1

Net Power - ISO 9249/SAE J1349

202 hp

151 kW

Net Power - ISO 9249 (DIN)

204 mhp

204 mhp

Emissions

Meets U.S. EPA Tier 4 Final, EU Stage V, Korea Stage V, China Nonroad Stage IV, Japan 2014 emission standards or India Bharat Stage III, Eurasian Economic Union Stage IIIA, UN ECE R96 Stage IIIA emission standards, equivalent to U.S. EPA Tier 3/ EU Stage IIIA.

Note (1)

Cat U.S. EPA Tier 4 Final, EU Stage V, Korea Stage V, China Nonroad Stage IV, Japan 2014 engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels up to: 20% biodiesel FAME (fatty acid methyl ester)*; 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Cat engines meeting Eurasian Economic Union Stage IIIA, UN ECE R96 Stage IIIA emission standards, equivalent to U.S. EPA Tier 3/ EU Stage IIIA, are compatible with diesel fuel blended with the following lower-carbon intensity fuels up to: 100% biodiesel FAME (fatty acid methyl ester)**; 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details. *Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (For use of blends higher than 20% biodiesel, consult your Cat dealer). **For use of blends higher than 20% biodiesel, consult your Cat dealer.

Note (2)

Net power advertised is the power available at the engine flywheel when the engine is equipped with a fan, air cleaner, clean emissions Module (when equipped) and alternator. Advertised power is tested per the specified standard in effect at the time of manufacture.

Weights

Operating Weight

44881 lb

20358 kg

Service Refill Capacities

Fuel Tank

84.5 gal (US)

320 l

DEF Tank

4.2 gal (US)

16 l

Standard

Operating Weight

44881 lb

20358 kg

Width of Standard Shoe

22 in

550 mm

Ground Contact Area

4900 in²

3.2 m²

Ground Pressure

9.1 psi

63 kPa

Low Ground Pressure (LGP)

Operating Weight

50181 lb

22762 kg

Width of Standard Shoe

31 in

800 mm

Ground Contact Area

7136 in²

4.6 mm²

Ground Pressure

7 psi

48.5 kPa

Waste Handler

Operating Weight

45549 lb

20661 kg

Width of Standard Shoe

22 in

550 mm

Ground Contact Area

4900 in²

3.2 m²

Ground Pressure

9.2 psi

63.3 kPa

Dimensions

Overall Machine Length*

275.6 in

7001 mm

Machine Height - Top of Cab

130.9 in

3325 mm

Height - Top of Stack

115.7 in

2940 mm

Overall Machine Height - Bucket Fully Raised

212.7 in

5402 mm

Overall Machine Width without Bucket: With Standard Tracks - 550 mm (21.6 in) Shoes

94.5 in

2400 mm

Note

*With General Purpose bucket and extra duty teeth.

Undercarriage

Track Gauge

72.8 in

1850 mm

Track on Ground

100 in

2542 mm

Track Rollers/Shoes - Each Side

7 / 38

Buckets

Capacity - General Purpose

3.2 yd³

2.5 m³

Capacity - Multi-Purpose

2.6 yd³

2 m³

Capacity - Performance Series

3.7 yd³

2.8 m³

Width - General Purpose

101.2 in

2571 mm

Width - Multi-Purpose

101.3 in

2575 mm

Width - Performance Series

105.2 in

2671 mm

Air Conditioning System

Air Conditioning

The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.1 kg of refrigerant which has a CO2 equivalent of 1.573 metric tonnes.

Standard Equipment

NOTE

Power Train

Operator Environment

Cat Technology

Undercarriage

Buckets

Service and Maintenance