926M Aggregate Handler Small Wheel Loader

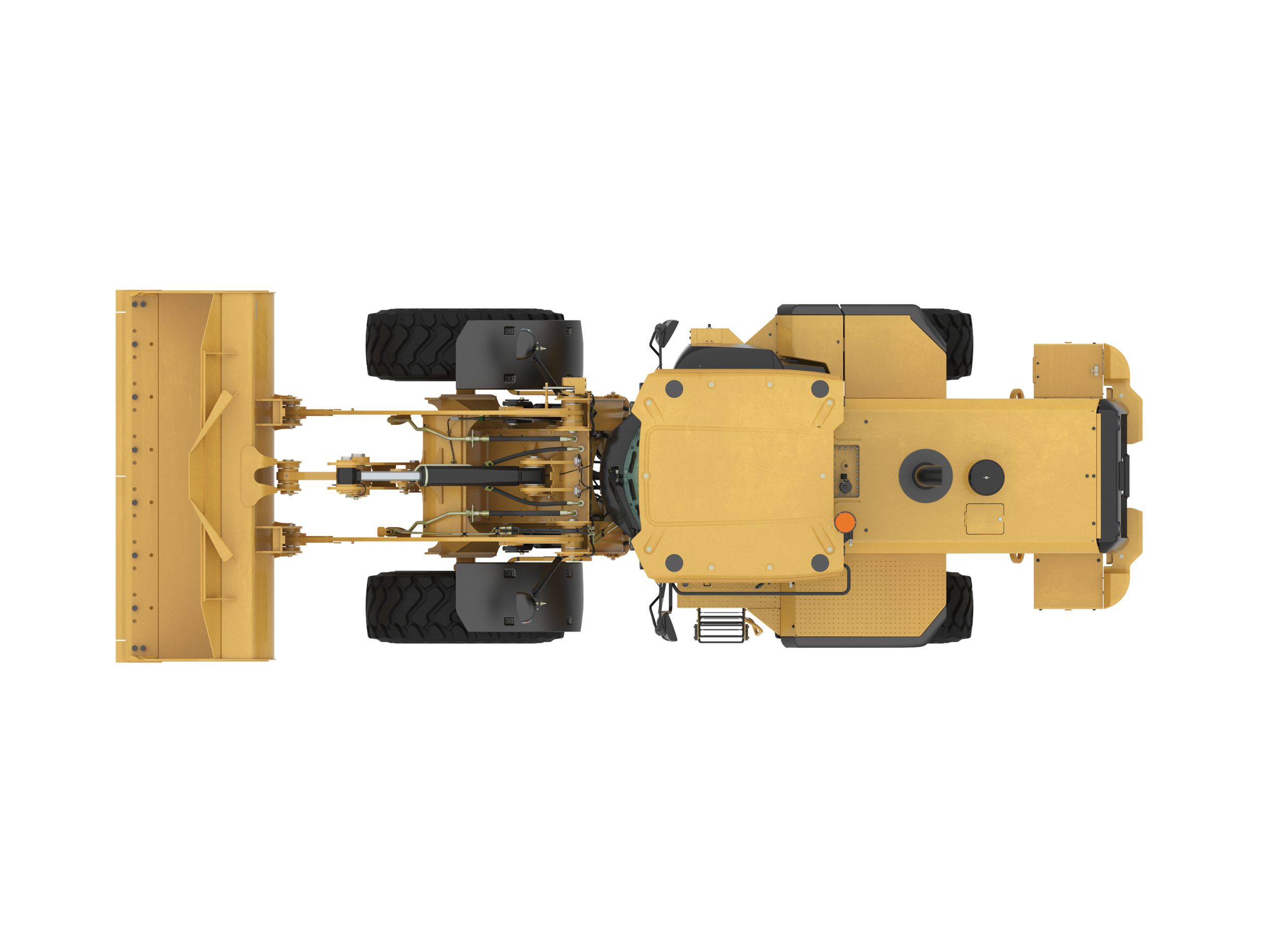

The Cat® 926M Aggregate Handler sets a new standard for productivity, fuel efficiency and comfort. A high torque, low speed C7.1 engine works in concert with an intelligent hystat power train to deliver fuel efficiency as standard. The optimized Z-bar loader linkage combined with long wear life Performance Series buckets delivers improved payloads and bucket longevity. Extremely low sound levels, large spacious cab and intuitive controls keep you working comfortably all day and even all night! Experience this industry benchmark.

Specifications

Equipment

Product Brochures

Attachments

Units:

Engine

Maximum Gross Power

168 hp

125 kW

Bore

4 in

105 mm

Stroke

5 in

135 mm

Displacement

427 in³

7.01 l

Emissions

The Cat C7.1 engine meets U.S. EPA Tier 4 Final, EU Stage V and Korea Tier 4 Final emission standards.

Maximum Rated Gross Power - ISO 14396

168 hp

125 kW

Maximum Gross Torque - ISO 14396 (Standard Power Mode: Range 1-3*)

586 ft·lbf

795 N·m

Note (2)

Net power ratings are tested at the reference conditions for the specified standard and denote power available at the flywheel when the engine is equipped with alternator, air cleaner, emission components and fan at specified speed.

Maximum Gross Power - Maximum Engine Speed (Performance Power Mode: Range 1-4)

1800 r/min

1800 r/min

Maximum Gross Power - ISO 14396 (Performance Power Mode: Range 1-4)

168 hp

125 kW

Maximum Net Torque - SAE J1349 (Standard Power Mode: Range 1-3*)

573 ft·lbf

777 N·m

Note (3)

No derating required up to 3000 m (10,000 ft) altitude. Auto derate protects hydraulic and transmission systems.

Maximum Gross Power - ISO 14396 (Standard Power Mode: Range 1-3*)

160 hp

119 kW

Maximum Gross Power - Maximum Engine Speed (Standard Power Mode: Range 1-3*)

1600 r/min

1600 r/min

Engine Model

Cat® C7.1

Maximum Gross Torque - ISO 14396 (Performance Power Mode: Range 1-4)

601 ft·lbf

815 N·m

Maximum Net Torque - SAE J1349 (Performance Power Mode: Range 1-4)

588 ft·lbf

797 N·m

Note (1)

*Range 4 power and torque is equal to Performance Mode with Caterpillar Power by Range technology.

Maximum Gross Power - ISO 14396 (metric) (Performance Power Mode: Range 1-4)

170 hp

125 kW

Net Power - ISO 9249 (metric) at Minimum Fan Speed (Performance Power Mode: Range 1-4)

166 hp

122 kW

Net Power - ISO 9249 at Minimum Fan Speed (Performance Power Mode: Range 1-4)

164 hp

122 kW

Net Power - SAE J1349 at Minimum Fan Speed (Performance Power Mode: Range 1-4)

163 hp

122 kW

Maximum Net Torque - ISO 9249 (Performance Power Mode: Range 1-4)

587 ft·lbf

796 N·m

Maximum Gross Power - ISO 14396 (metric) (Standard Power Mode: Range 1-3*)

162 hp

119 kW

Maximum Rated Gross Power - ISO 14396 (metric)

170 hp

125 kW

Net Power - ISO 9249 at Minimum Fan Speed (Standard Power Mode: Range 1-3*)

156 hp

116 kW

Net Power (Standard Power Mode: Range 1-3*)

1600 r/min

1600 r/min

Net Power (Performance Power Mode: Range 1-4)

1800 r/min

1800 r/min

Net Power - SAE J1349 at Minimum Fan Speed (Standard Power Mode: Range 1-3*)

156 hp

116 kW

Maximum Net Torque - ISO 9249 (Standard Power Mode: Range 1-3*)

572 ft·lbf

776 N·m

Net Power - ISO 9249 (metric) at Minimum Fan Speed (Standard Power Mode: Range 1-3*)

158 hp

116 kW

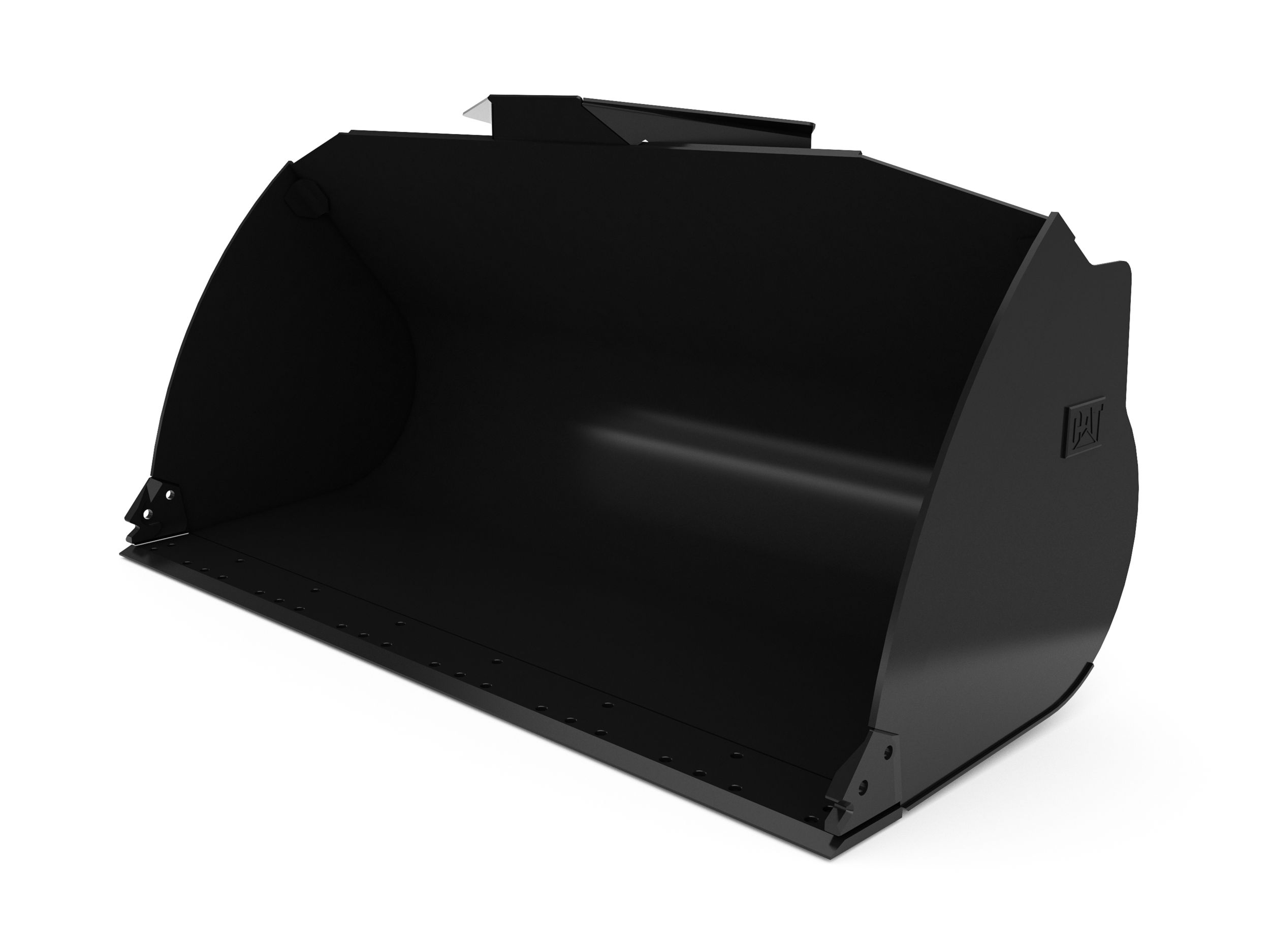

Buckets

Bucket Capacities

2.5-5.0 m3 (3.3-6.5 yd3)

Weights

Operating Weight

28577 lb

12963 kg

Note (2)

~Aggregate Handler equipped with full counterweight, optional guards, roading fenders, and cold start package.

Operating Weight (2)

12 963 kg (28,577 lb)~

Operating Weight (1)

12 891 kg (28,418 lb)**

Note (1)

**Aggregate Handler machine equipped with full counterweight and optional guards.

Cab

ROPS

ISO 3471:2008

Service Refill Capacities

Diesel Exhaust Fluid (DEF) Tank

5 gal (US)

19 l

Steering

Steering Cylinder, Double Acting - Stroke

17.2 in

438 mm

Loader Hydraulic System

Relief Pressure - Tilt Cylinder

4061 psi

28000 kPa

Tilt Cylinder, Double Acting - Stroke

20.3 in

516 mm

Maximum Flow - Implement Pump

40 gal/min

150 l/min

Maximum Working Pressure - Implement Pump

3771 psi

26000 kPa

Transmission

Forward and Reverse - Range 2

8 mile/h

13 km/h

Service Refill Capacities

Engine Crankcase

5.3 gal (US)

20 l

Steering

Note (1)

Steering system uses a dedicated load sensing variable displacement pump with dual double acting cylinders.

Loader Hydraulic System

Cycle Times - Performance (HP+) at 1,800 rpm/Standard Power Mode at 1,600 rpm - Total Cycle Time

9.6/10.5 seconds

Steering

Maximum Working Pressure - Steering Pump

3500 psi

24130 kPa

Loader Hydraulic System

Tilt Cylinder, Double Acting - Bore Diameter

5.5 in

140 mm

Power Train

Rear Axle - Traction Aid - Optional

Limited slip differential

Transmission

Forward and Reverse - Range 3

17 mile/h

27 km/h

Loader Hydraulic System

Tilt Cylinder, Double Acting - Rod Diameter

3 in

75 mm

Power Train

Note (3)

*Differential front locking axle can be engaged on the go at full torque to 10 km/h (6.2 mph) on the 926M.

Service Refill Capacities

Hydraulic Tank

23.8 gal (US)

90 l

Power Train

Front Axle

Fixed

Loader Hydraulic System

Lift Cylinder, Double Acting - Rod Diameter

2.4 in

60 mm

Lift Cylinder, Double Acting - Bore Diameter

4.3 in

110 mm

Steering

Maximum Flow - Steering Pump

34 gal/min

130 l/min

Service Refill Capacities

Hydraulic System - Including Tank

42.3 gal (US)

160 l

Transmission

Forward and Reverse - Range 1*

1-13 km/h (0.6-8 mph)

Service Refill Capacities

Cooling System

7.9 gal (US)

30 l

Power Train

Rear Axle - Oscillation Angle by Tire Size - 17.5 R25

± 13.5 degrees

Steering

Steering Cylinder, Double Acting - Bore Diameter

2.8 in

70 mm

Steering Cycle Times - Full Left to Full Right - Maximum RPM: 90 rpm Steering Wheel Speed

2.4 s

2.4 s

Cab

FOPS

ISO 3449:2005 LEVEL II

Power Train

Note (2)

Offset rims available to meet European roading requirements.

Front Axle - Traction Aid*

Locking differential (standard)

Rear Axle - Oscillation Angle by Tire Size - 20.5 R25, 550/65, 600/65, 650/65

± 10.5 degrees

Steering

Steering Cylinder, Double Acting - Rod Diameter

1.6 in

40 mm

Loader Hydraulic System

Maximum Flow - Implement Pump - 4th Function Maximum Flow*

40 gal/min

150 l/min

Steering

Note (2)

Flow values listed are for a machine running in Performance Power Mode (1,800 rpm).

Power Train

Note (1)

Power train is governed by the Caterpillar exclusive Intelligent Power Management system to deliver peak performance and efficiency.

Service Refill Capacities

Rear Axles

6.6 gal (US)

25 l

Transmission

Forward and Reverse - Range 4

25 mile/h

40 km/h

Steering

Steering Cycle Times - Full Left to Full Right - Minimum RPM: Pump Flow Limited

2.8 s

2.8 s

Air Conditioning System

Air Conditioning

The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential – 1430. The system contains 1.9 kg of refrigerant which has a CO2 equivalent of 2.717 metric tonnes.

Loader Hydraulic System

Relief Pressure - Tilt Cylinder - 3rd and 4th Function Relief Pressure

4061 psi

28000 kPa

Service Refill Capacities

Fuel Tank

51.5 gal (US)

195 l

Loader Hydraulic System

Relief Pressure - Tilt Cylinder - 3rd and 4th Function Maximum Working Pressure

3771 psi

26000 kPa

Power Train

Brakes - Service

Inboard wet disc

Cab

Note (1)

* Measurements were conducted with cab doors and windows closed and at 70% of maximum engine cooling fan speed. Sound level may vary at different engine cooling fan speeds.

Loader Hydraulic System

Lift Cylinder, Double Acting - Stroke

28.7 in

728 mm

Service Refill Capacities

Front Axles

6.9 gal (US)

26 l

Loader Hydraulic System

Cycle Times - Performance (HP+) at 1,800 rpm/Standard Power Mode at 1,600 rpm - Dump (at Maximum Lift Height)

1.5/1.7 seconds

Cycle Times - Performance (HP+) at 1,800 rpm/Standard Power Mode at 1,600 rpm - Raise (Ground Level to Maximum Lift)

5.5/6.2 seconds

Note (2)

Flow values listed are for a machine running in Performance Power Mode (1,800 rpm).

Service Refill Capacities

Transmission - Gear Box

2.2 gal (US)

8.5 l

Cab

Declared Sound Levels

Declared Sound Levels

– Operator Sound Pressure Level (ISO 6396:2008): 68 dB(A)*

– Exterior Sound Power Level (ISO 6395:2008): 101 dB(A)*

– Operator Sound Pressure Level (ISO 6396:2008): 68 dB(A)*

– Exterior Sound Power Level (ISO 6395:2008): 101 dB(A)*

Power Train

Rear Axle

Oscillating

Loader Hydraulic System

Note (1)

Implement system uses a dedicated load sensing variable displacement pump with dual double acting lift cylinders and a single double acting tilt cylinder.

Power Train

Brakes - Parking

Spring applied hydraulically released

Transmission

Note

* Creeper control allows maximum speed range adjustability from 1 km/h (0.6 mph) to 13 km/h (8 mph) in Range 1 through the secondary display when equipped. Factory default is 7 km/h (4.4 mph).

Loader Hydraulic System

Note (3)

* 3rd and 4th function flow is fully adjustable from 20% to 100% of maximum flow through the secondary display when equipped.

Cycle Times - Performance (HP+) at 1,800 rpm/Standard Power Mode at 1,600 rpm - Float Down (Maximum Lift to Ground Level)

2.6/2.6 seconds

Maximum Flow - Implement Pump - 3rd Function Maximum Flow*

40 gal/min

150 l/min

Operating Specifications

Note (1)

**Aggregate Handler machine equipped with full counterweight and optional guards.

Full Turn Tip Load (2)

8148 kg (17,962 lb)~

Full Turn Tip Load (1)

8047 kg (17,740 lb)**

Note (2)

~Aggregate Handler equipped with full counterweight, optional guards, roading fenders, and cold start package.

Sustainability

Recyclability

94%

Standard Equipment

POWER TRAIN

HYDRAULICS

ELECTRICAL

OPERATOR ENVIRONMENT

OTHER STANDARD EQUIPMENT